Xinda Reciprocating Single Screw Compounding Extruder

The performance of single and twin-screw extruders, which dominate the extrusion industry, has been unable to meet the requirements of compounding, filling, strengthening, toughening, and other modifications. To meet the production process requirements, it has gradually become a trend to use co-kneader (reciprocating single screw extruder) to produce some high-tech and high-value-added products.

The reciprocating single-screw intensive extruder has the characteristics of uniform shearing, high dispersion, high filling, stretching melt, etc., and combines the advantages of single and twin-screw extruders. The unique working principle, coupled with a complete set of threaded components and supporting equipment, makes it more widely used. On one machine, mixing, mixing, plasticizing, dispersing, shearing, stretching, degassing and granulation can be achieved. The interfacial area that allows the melt to flow in the machine is much larger than general shear flow.

Product Quality Index

Energy Generation

Three Flights Plastic Co Kneader SJW (C) Series

| Model | SJW-45(M) | SJW-70(M) | SJW-100(M) | SJW-140(M) | SJW-200 |

|---|---|---|---|---|---|

| Screw Diameter(MM) | 45 | 70 | 100 | 140 | 200 |

| L/D | 15-25 | 15-25 | 15-25 | 15-25 | 20-25 |

| Main Motor Power(KW) | 15-30 | 55-75 | 90-132 | 160-220 | 250-280 |

| Max.Screw Speed(RPM) | 500 | 500 | 500 | 500 | 500 |

| Reference Output: KG/HOUR | 10-50 | 100-200 | 150-300 | 600-1000 | 1000-2000 |

Four Flights Plastic Co Kneader SKW & WKS Series

| Model | SKW-105 | SKW-125 | SKW-140 | WKS-120 |

|---|---|---|---|---|

| Screw Dia.(MM) | 105 | 125 | 140 | 120 |

| L/D | 15-22 | 15-22 | 15-22 | 9-15 |

| Main Motor Power(KW) | 200-280 | 350-450 | 550-650 | 250-280 |

| Max.Screw Speed(RPM) | 500 | 500 | 500 | 500 |

| Second-stage Screw dia.(MM) | 180 | 220 | 280 | 220 |

| Second-stage L/D | 7 | 7 | 7 | 7-8 |

| Second-stage Power(KW) | 75 | 110 | 132 | 90-132 |

| Reference Output:kg/h | 500-800 | 800-1500 | 1600-2000 | 1800-2500 |

Application

We provide our machinery users with consistent high productivity and product quality and the maximum cost effectiveness with XINDA technology. The XINDA twin screw (P)SHJ series is ideal for precise compounding of polyolefins,engineered plastics and other continuous processes.

Xinda 3D simulation of Co-Kneader

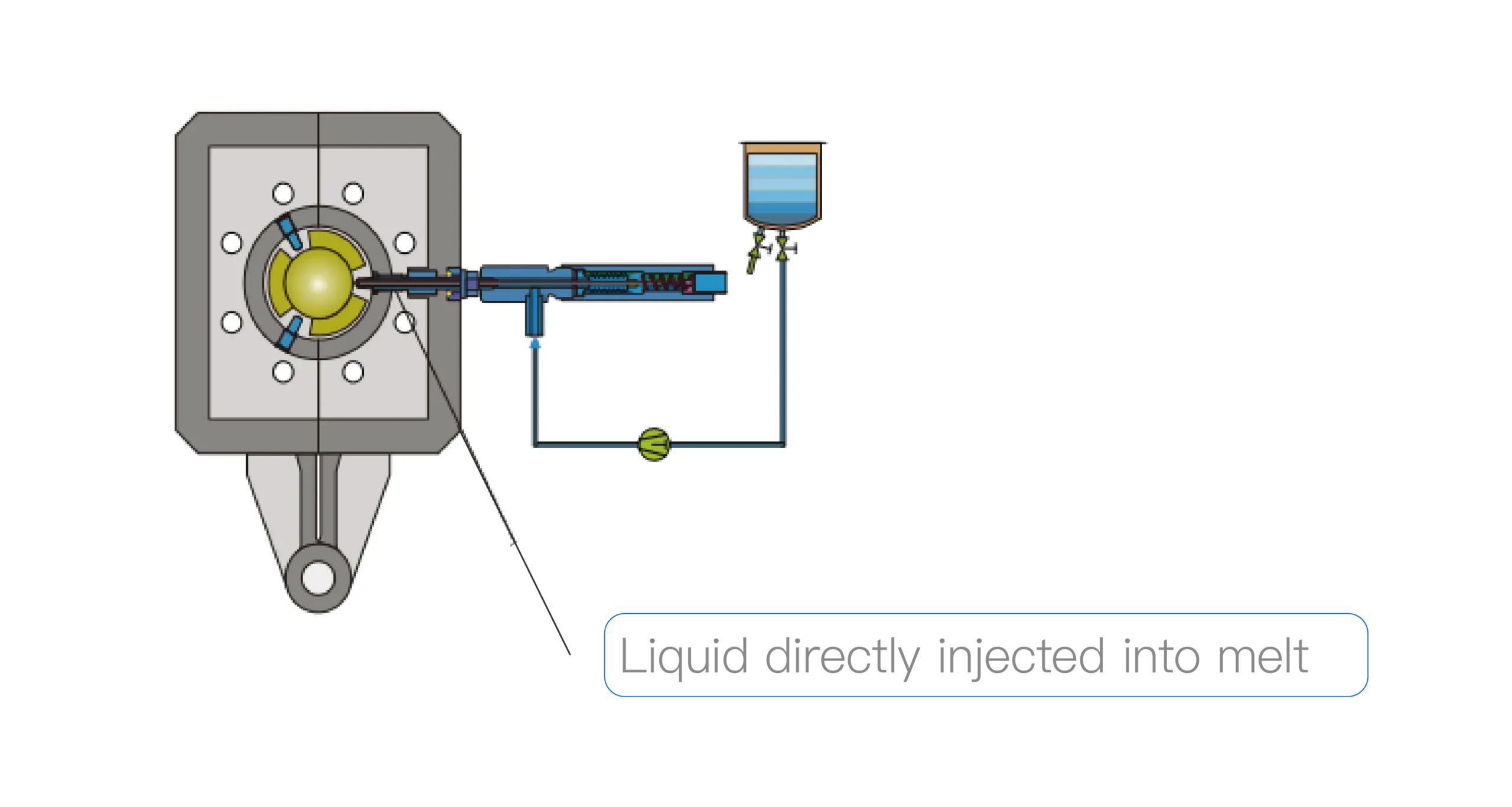

It shows the complete whole production line for different types of plastic compounds. A gravity feeding system, compounding extruder with solid and liquid feeding, eccentric water ring cutting, and drying system are used. All the lines have oil heating and cooling, accurate temperature control, and two cooling shafts.

We’re In Business

28+ years

Completed Successfully

2800+ projects

Features and advantages:

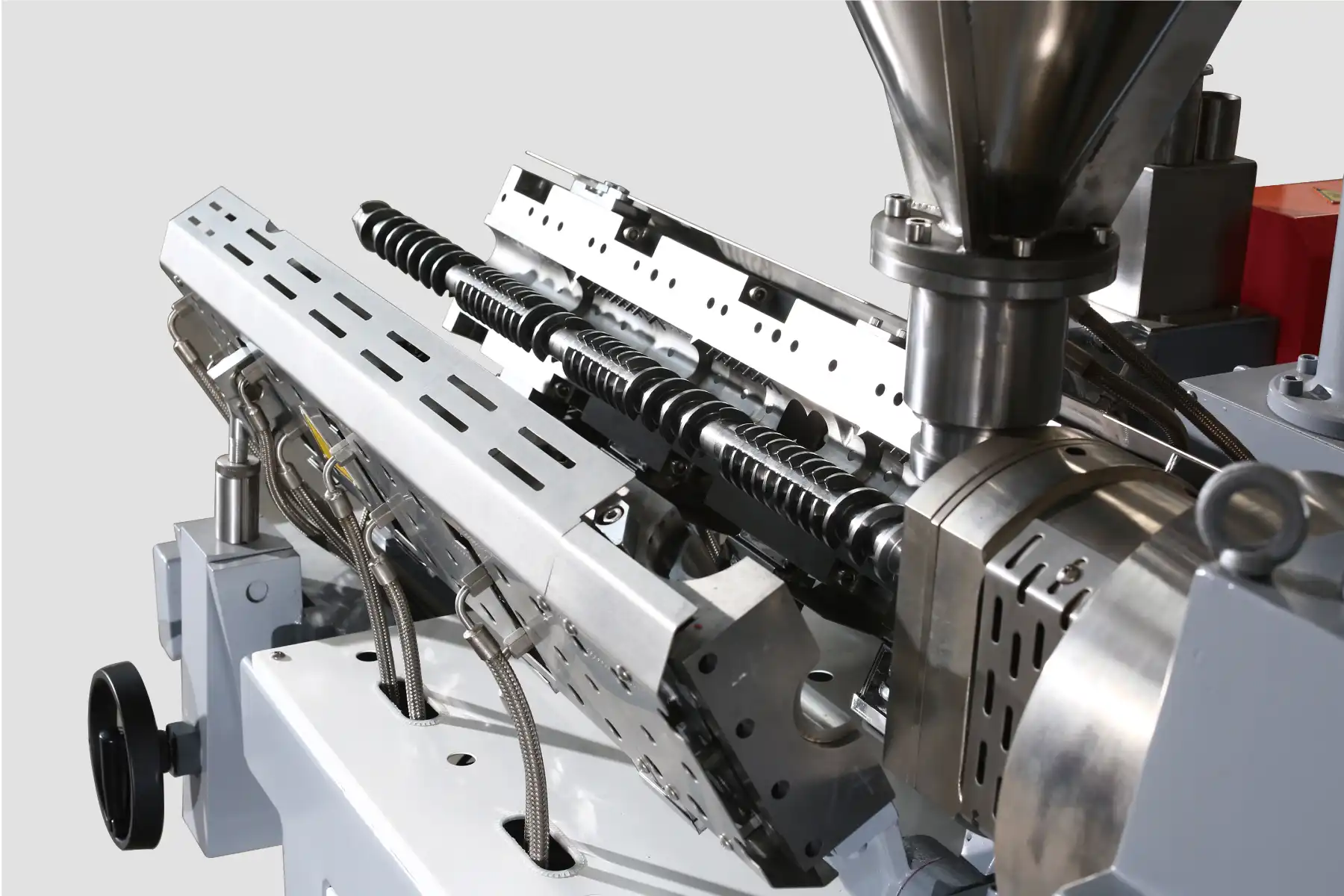

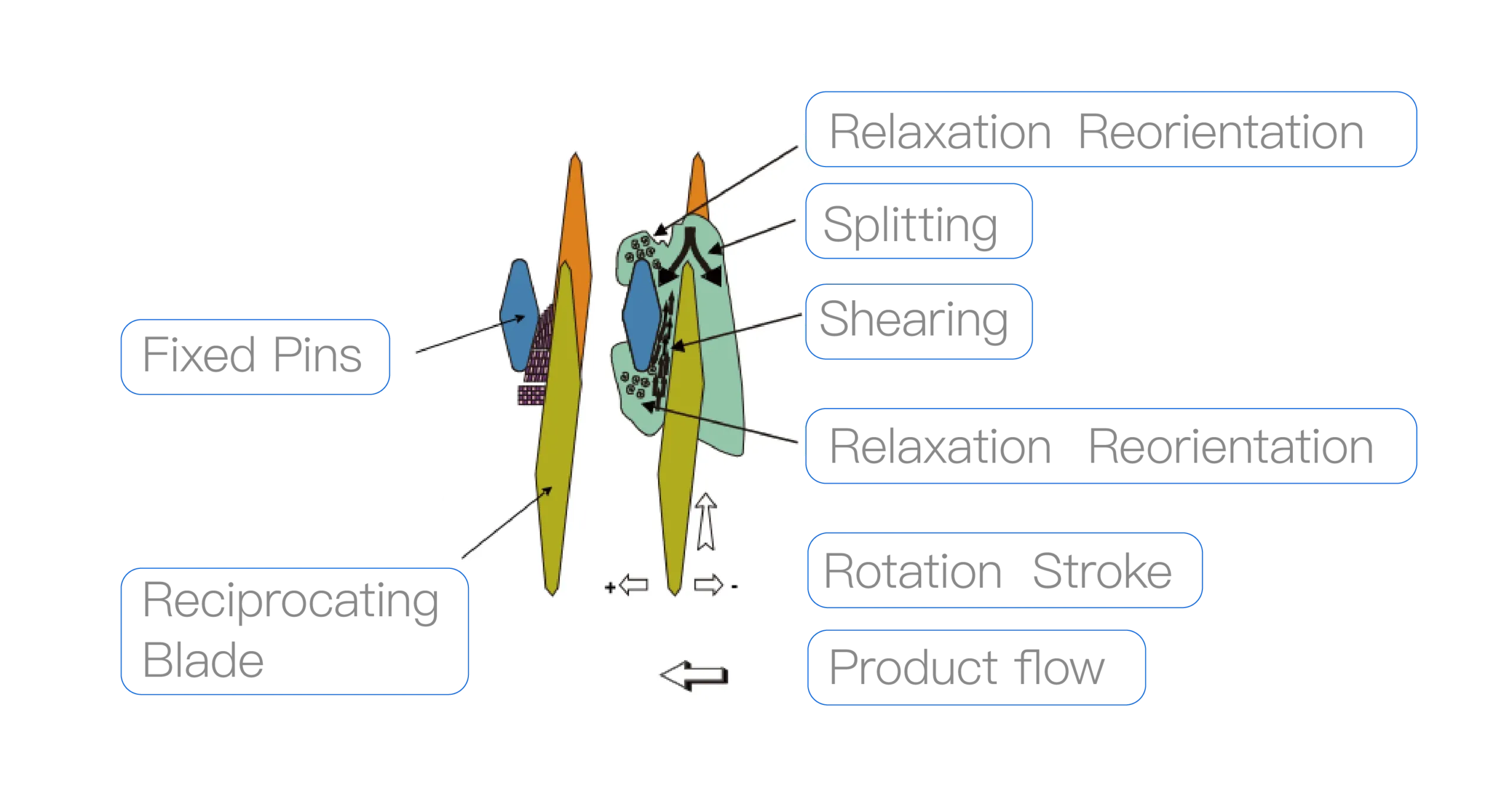

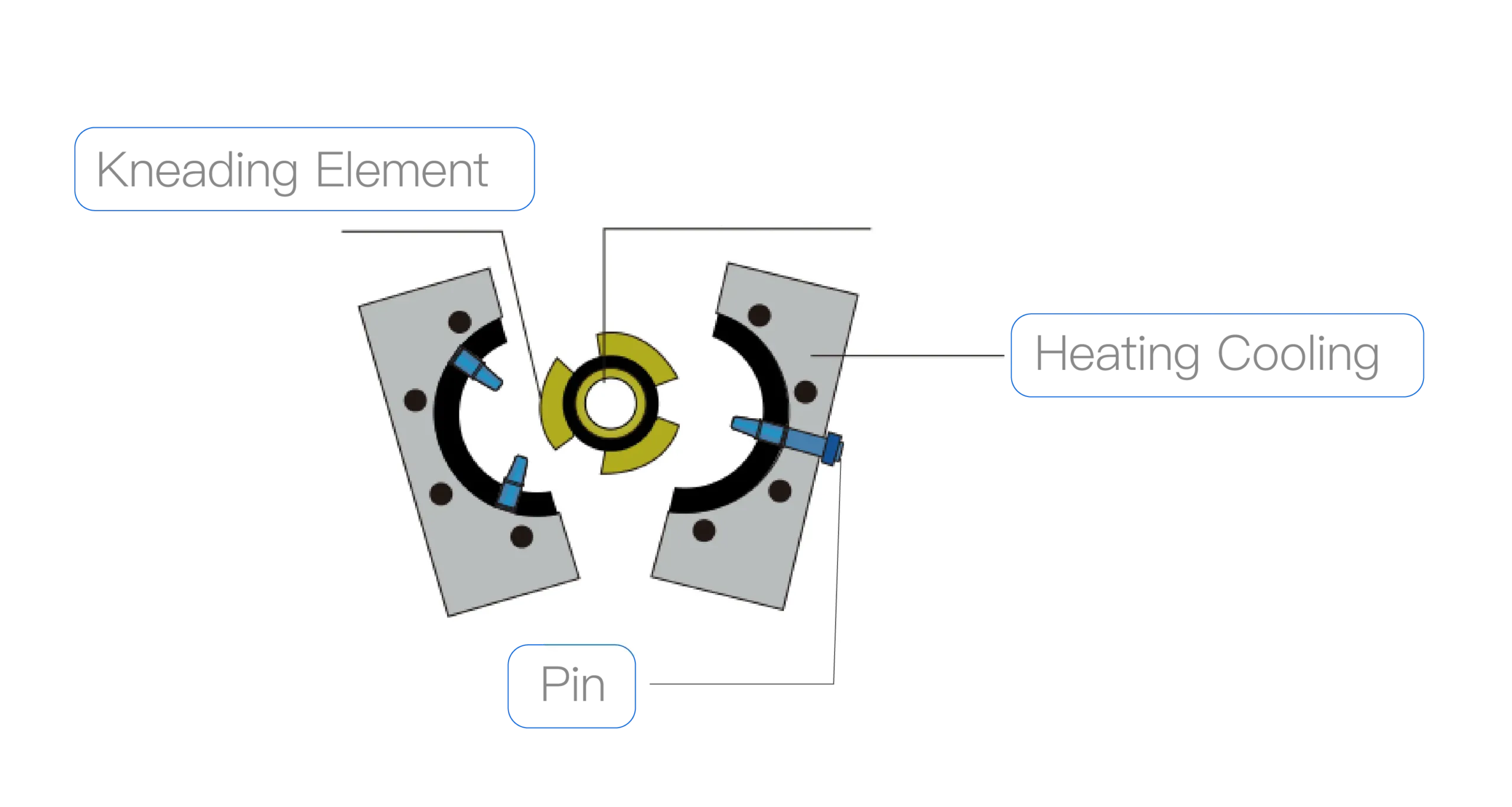

The extruder’s screw shaft is designed with unique modular screw blocks, allowing the screw to perform a reciprocating motion while rotating. This special movement, combined with the mixing blocks and the kneading pins on the barrel liner, enables the material to be mixed both radially and axially, enhancing the mixing effect.

- Design Flexibility: The unique reciprocating single screw and multi-tooth barrel design offer the advantages of both single and twin screw extruders, making it highly adaptable for processing, modifying, and granulating various plastics.

- Short Material Residence Time: With the shortest aspect ratio, materials have a short and controllable residence time, reducing thermal degradation and ensuring high dispersibility with low energy consumption and minimal use of pigments and additives.

- Effective Mixing: The system’s reciprocating motion allows for complete mixing, plasticizing, dispersing, homogenizing, and degassing in a single production cycle.

- Efficient Degassing: The vacuum device effectively removes moisture and volatile gases, making it ideal for processing semiconductors, conductive materials, and cable materials.

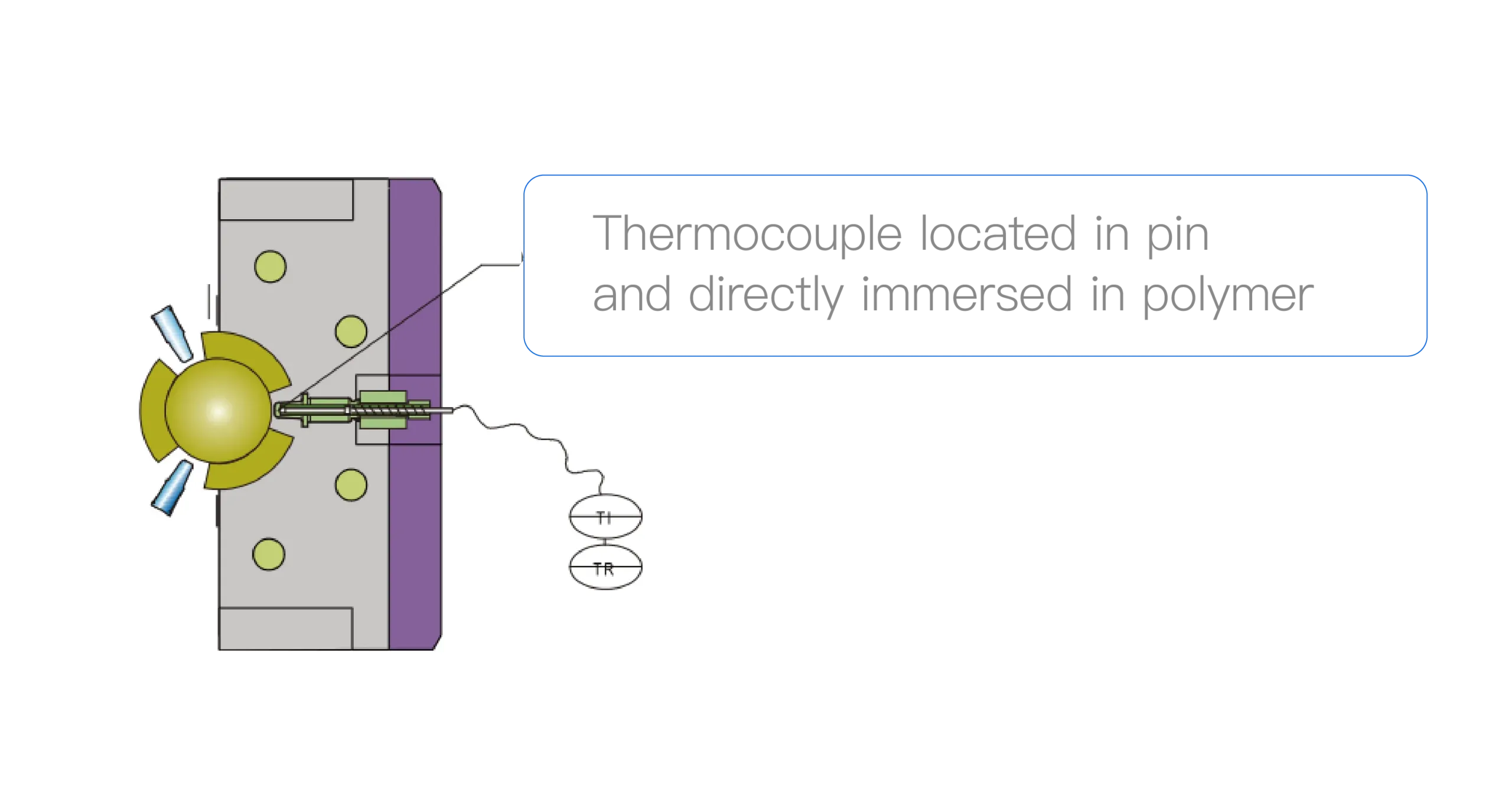

- Precise Temperature Control: Accurate and stable temperature control with minimal temperature difference is ideal for processing heat-sensitive and shear-sensitive materials.

- Easy Maintenance: The split barrel and segmented screw design facilitate quick and safe disassembly, cleaning, and repair, while low internal friction ensures stable, low-noise operation.

- Cost-Effective Operation: Equipped with semi-automatic and automatic screen-changing devices, the system reduces labor intensity, raw material consumption, and production costs.