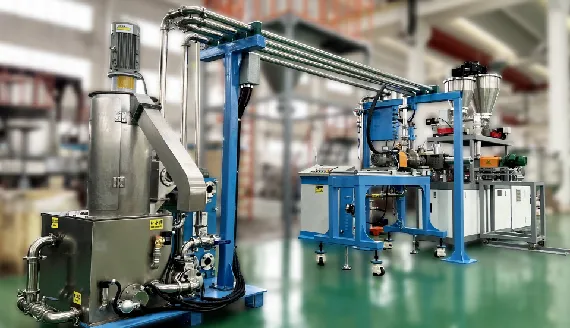

Compounding systems for hot melt adhesives

Hot melt adhesives have advantages over conventional adhesives in various ways. They are quickly processed, and rapidly become effective after cooling. Unlike solvent-based or 2-component adhesives, no hardening or reaction time is needed. Not only do they join widely different materials and surface types, but the joint also has a certain degree of flexibility. These special properties require nowadays special hot melt compounding systems.

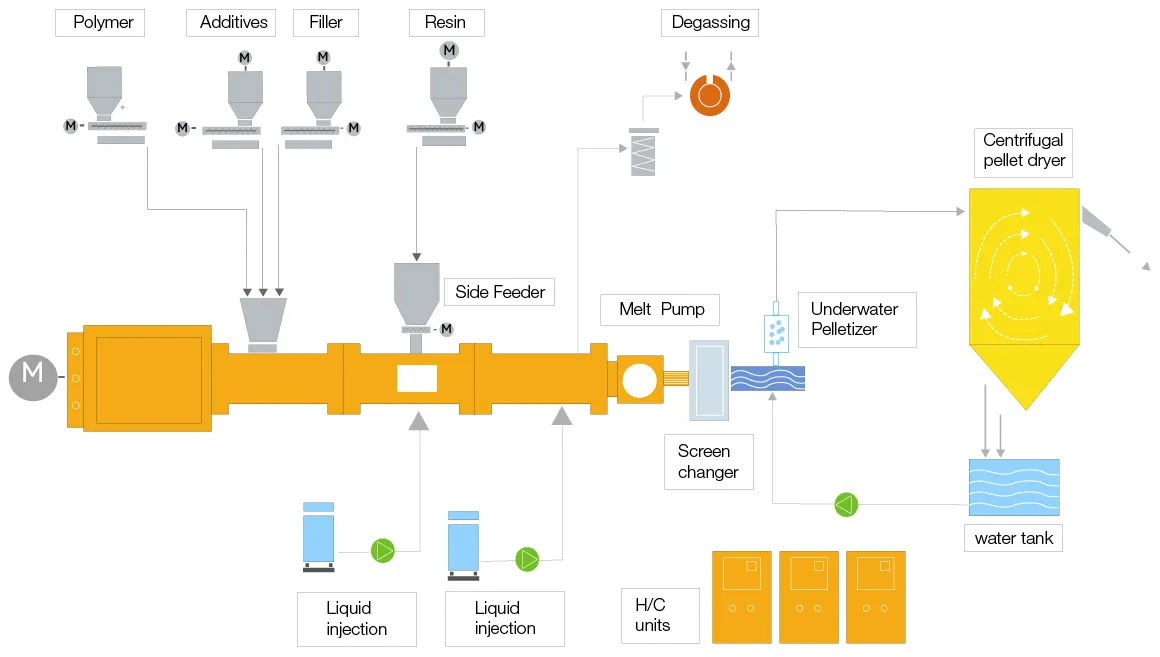

Processing steps:

Material Typical Compounding Plant Layout for Hot Melt

Application

Due to these special properties, hot melt are practically indispensable for many applications. Examples include the following hot melt or fusible adhesives applications:

> Coating cartons and boxes in the packaging industry

> Clothing, textiles and shoemaking, where HMA seams must withstand high loading both in use and during cleaning

> In electronics for fixing, cocooning or expanding modules

> Applications in the DIY area

Cases