Requirements for engineering plastic compounding

Engineering resins are plastic materials that have better mechanical and/or thermal properties than commodity plastics(PS,PVC,PE,PP, etc). Some types of engineering plastics have replaced metal and wood in many applications(eg. electrical and electronic, automobile, construction, machinery, and aerospace,etc.). Engineering plastics can be modified with various reinforced agents and additives to achieve high rigidity, low creep, remarkable mechanical strength, excellent heat resistance, and superior electrical insulation. Processing engineering plastics is very challenging.Some materials require a high degree of dispersion and distribution of fillers at high loading rates. Some materials are very sensitive to overheating and hydrolytic degradation. Thus selecting the right machine and optimizing equipment configuration becomes the top priority.

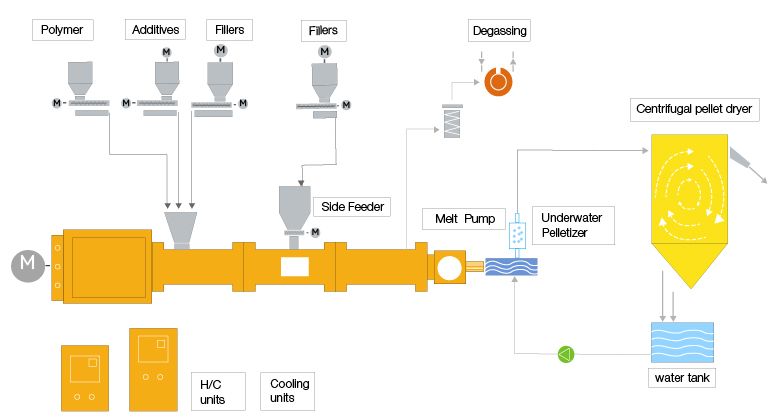

Processing steps:

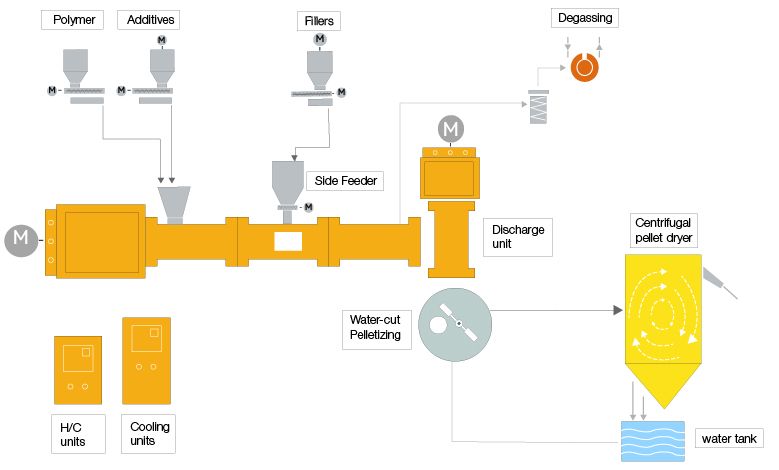

Material handling system-Compounding and extrusion- Water strand pelletizing system/Water ring cutting system/Underwater pelletizing system – Classify – Packing system

Xinda Co Kneader

engineering plastics compounding systems offer several specific benefits

> Precise temperature control minimize polymer degradation:

Temperature prob can immerse into melts through hollow pin in each processing zone so that we can get the accurate real-time temperature all the time .

> Gentle shearing minimize damage to high structure carbon black:

Co-kneader’s unique combination of screws, pins and barrels can provides low shear which will reduce the breakage to materials’ physical character.

> Uniform distribution of various additives:

Co-kneader’s multiple flights interacted with the pins provides excellent kneading effect by increasing the mixing circles. Thus various additives can be distributed evenly in the melts.

> High filling rate of fillers:

Opening of two or three inlets & low shearing allow the maximum loading rate of inorganic powders.

> Flexible screw configuration:

Co-kneader’s screw profile can be changed by adjusting the serial of modular designed screw. Thus various formulations can be processed on the same machine.

Why Xinda’s Twin Screw Extruder different?

> Clamshell Barrel:

Clamshell Barrel: The barrel can be quickly opened for cleaning and maintenance. According to material variety and different technological requirements,it can be flexible combined into an ideal structure to improve the overall utilization rate of the equipment.