about the extruder

PVC Cable Compounds

Soft PVC cable compounds are the most economic polymer that used for cable of voltage lower than 10KV. Due to different temperature requirements, PVC insulation compounds are mostly customized for different cable and wire applications. It is very important to achieve a high filling rate of inorganic powders in order to get a competitive price. Evenly dispersing and distribution of various additives into melted polymer is the key to obtain a homogeneously gelation. Low process temperature is also required for a better quality.

Product Quality Index

Energy Generation

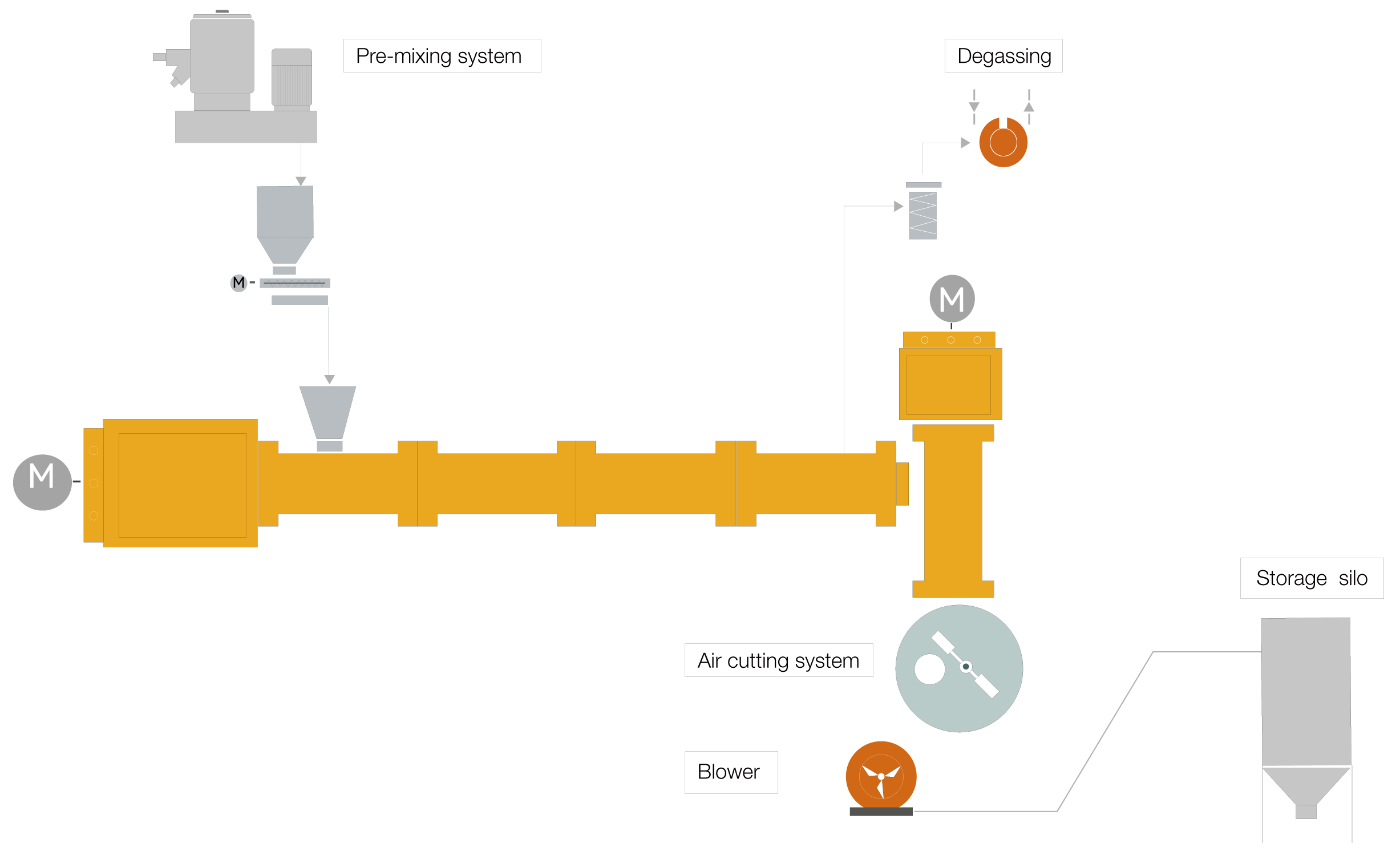

Processing Steps

Hot/Cold mixing system-Compounding and extrusion- Air cooling die face pelletizer-Air cooling & conveying system – Classify – Packing system

Xinda in Cable Compounding Industry

Xinda Co-Kneader is used by well-known cable companies worldwide, specializing in the production of PVC, HFFR, XLPE, PEX cross-linkable and semi-conductive cable compounds.

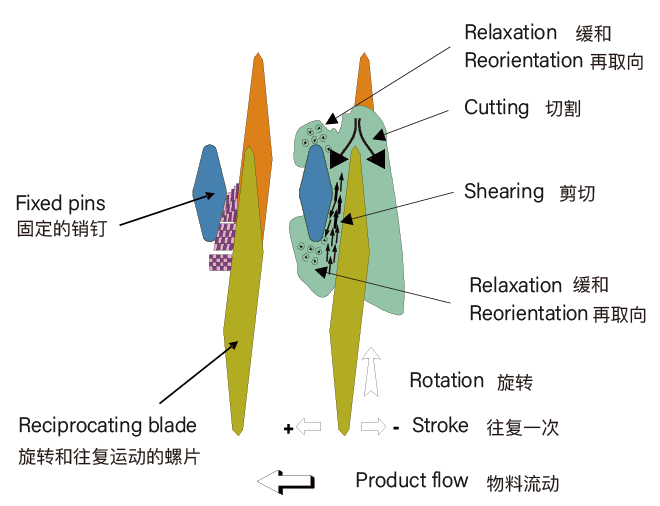

Gentle Shearing

Low Process Temperature

Precise temperature control

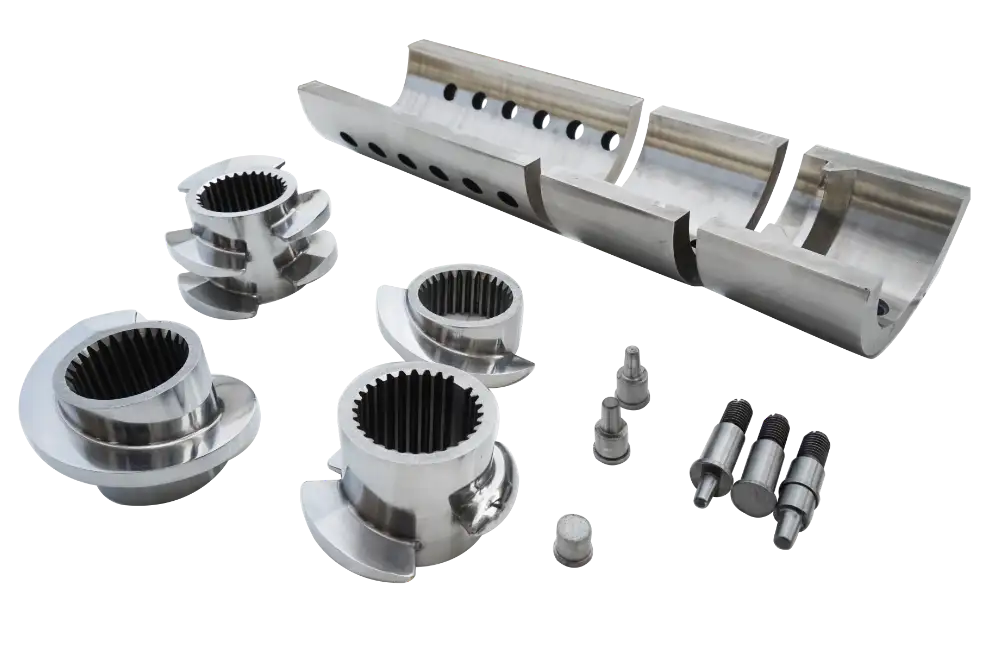

Flexible Screw Configurations

High Filling Rate of Inorganic Powder

Uniform Distribution of Various Additives

Working Principle

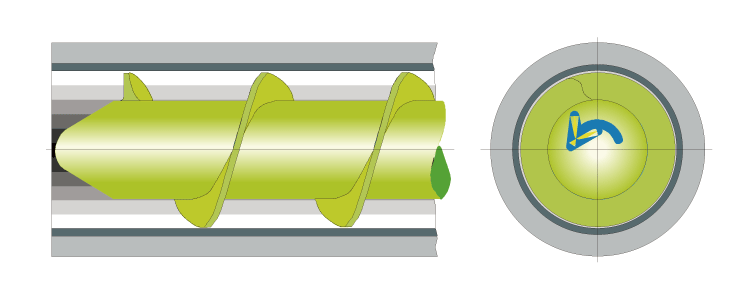

Classic Single Screw

Co Kneader

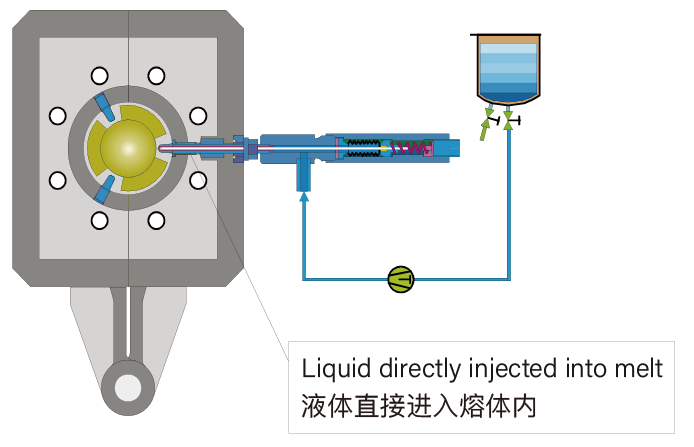

Liquid Injection System

The liquids are directly injected into the melt at the appropriate time and place

The process is extremely accurate, safe and hazard free

There are no losses due to volatilisation and no deposits on metal surface

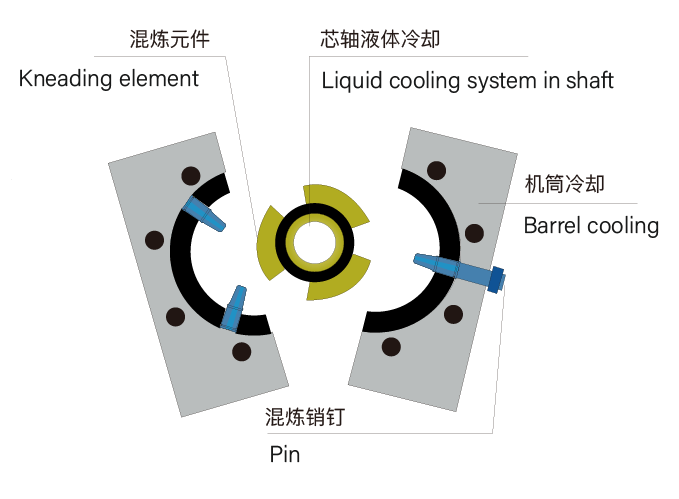

Shear Mechanism in the Co-Kneader

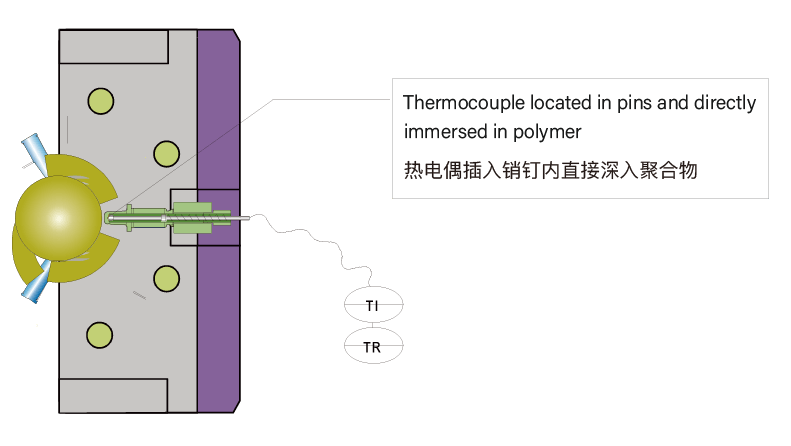

Hollow Pins for Thermocouple

Direct immersion in polymer

Precise melt temperature

Temperature stability of the process

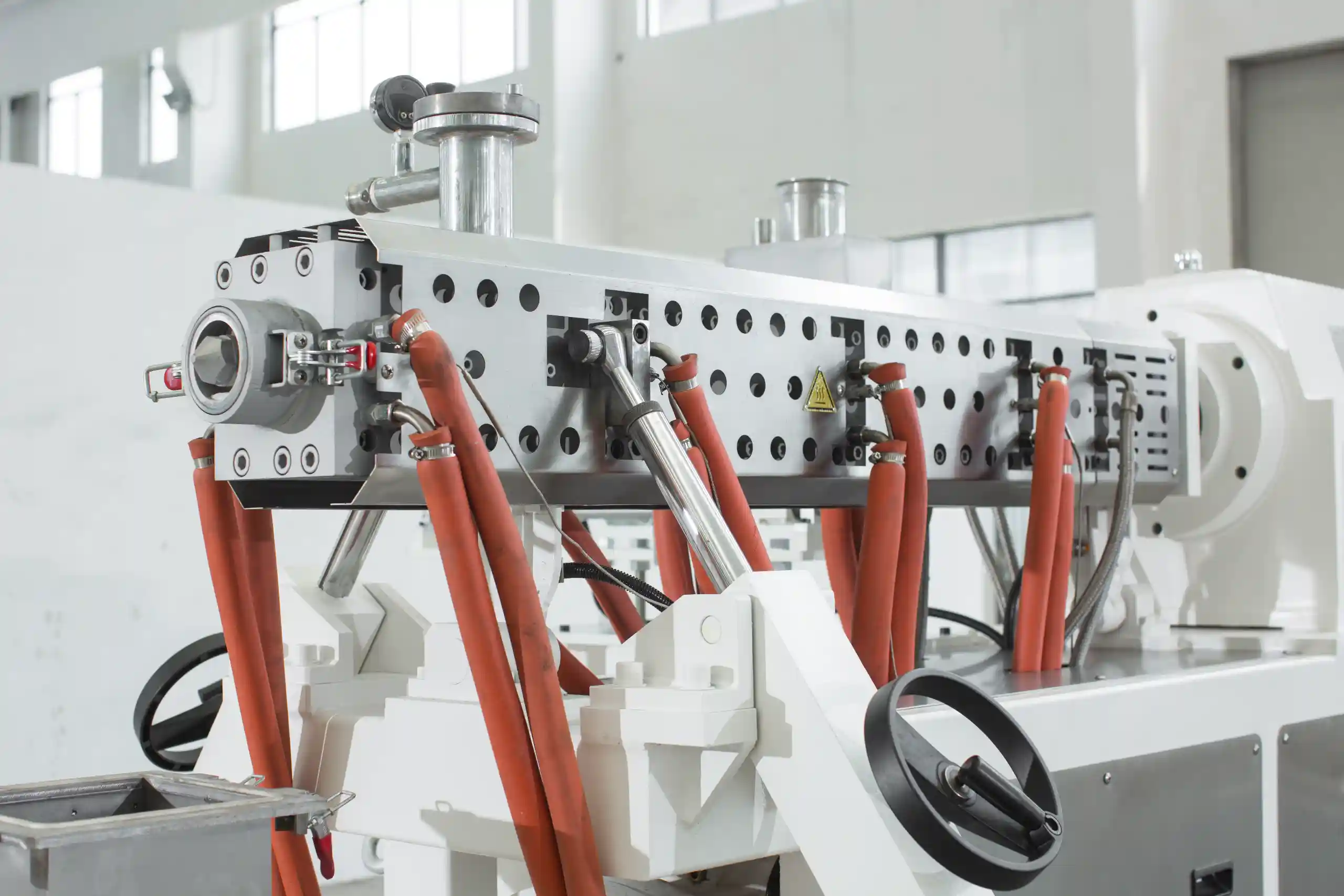

Temperature Control

Barrel: Liquid or electrically heated / Water Cooled

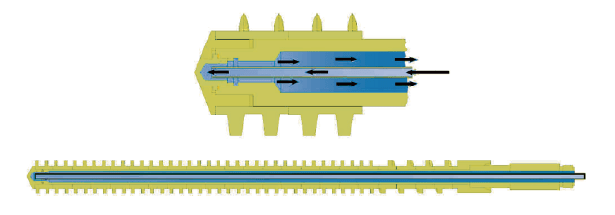

Shaft: Liquid heated/ cooled

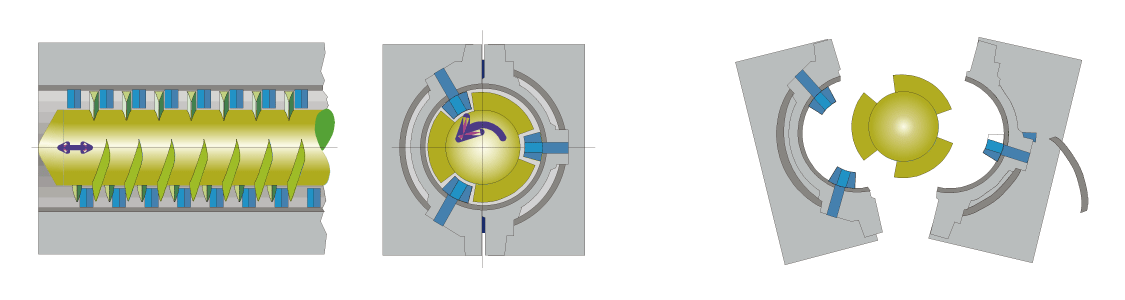

Easy adaptation of screw configuration

The screw consists of individual elements, that can easily be exchanged or replaced