Bio plastics are a large family of different materials, not just one material. They consist of a whole family of materials with different properties and applications. According to European Bioplastics, plastic materials are defined as bioplastics if they are bio-based, biodegradable or both.

Biodegradable Compounds:

With extensive experience in the plastic compounding industry, together with broadly based Xinda process expertise in compounding, make Xinda a pioneer in the biodegradable plastics industry.

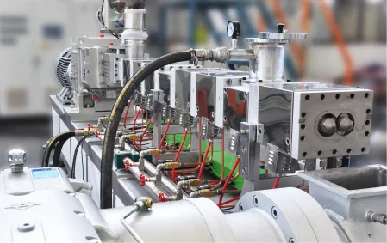

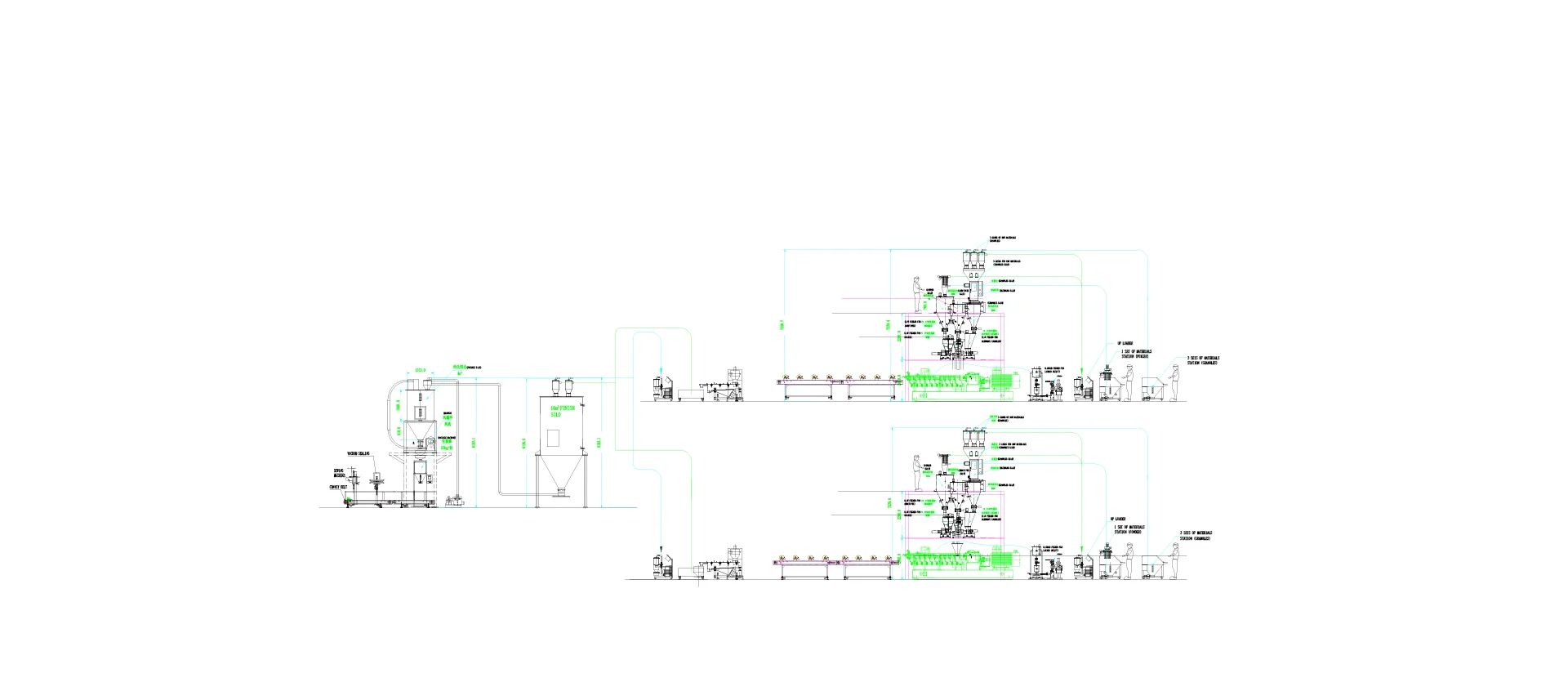

Xinda twin-screw extruder adopts modular design, and its main advantage is multi-functional configuration.Processing tasks can be optimally accomplished with only a few barrel and screw variations. We will make the detailed solution according to your specific application for Bio-degradable products.

Xinda Twin-screw extrusion lines offer major advantages for manufacturing biodegradable compounds:

> process flexibility, reduced downtime between batches and simple product changeover.

> dedicated screw profiles for homogenous mixing quality.

> Moderate shear and low shear stress without destroying delicate fillers.

> Using high-accuracy gravimetric feeders to introduce the raw materials into the twin screw extruder, which can reliably feed biomas with poor liquidity such as starch.