about the extruder

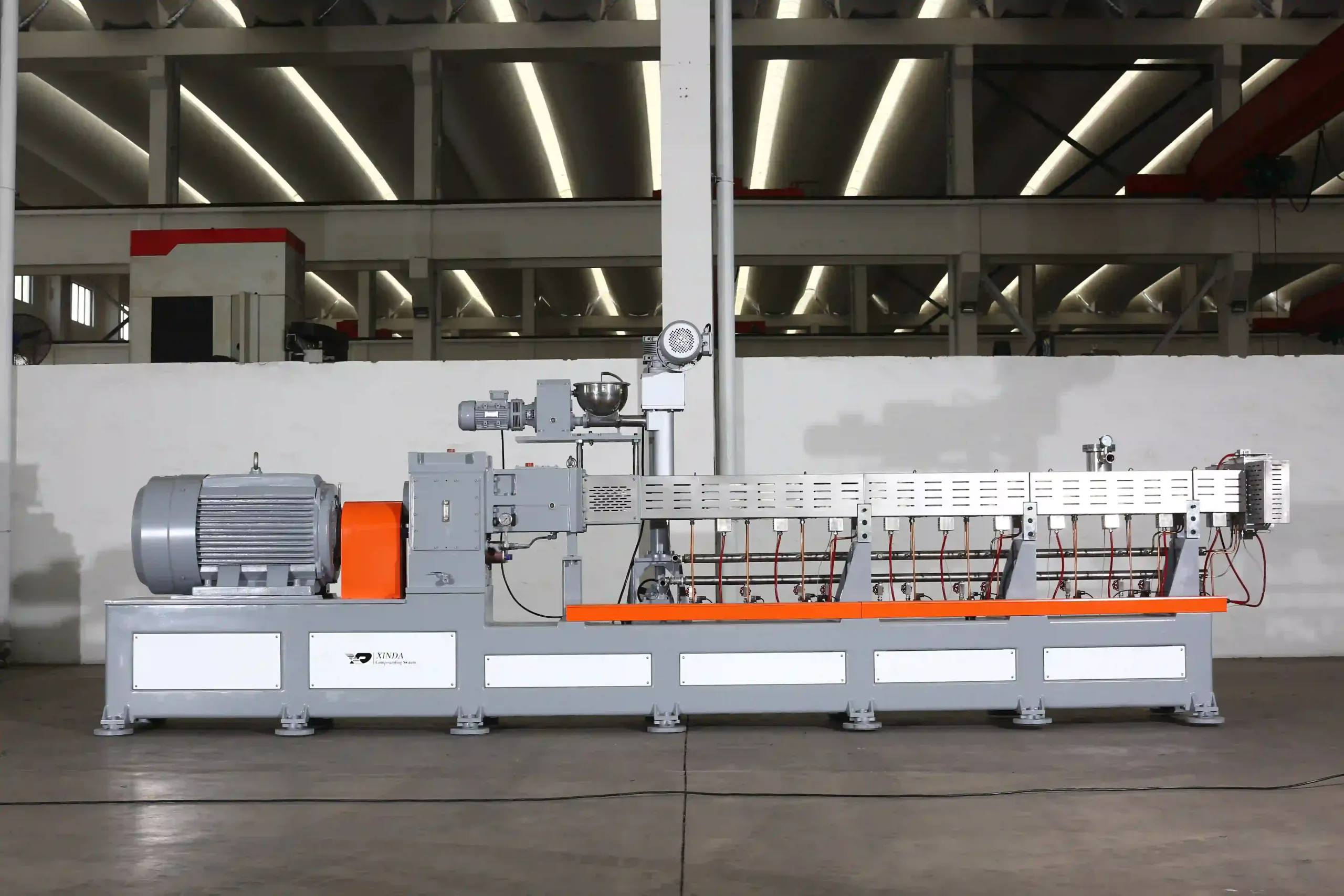

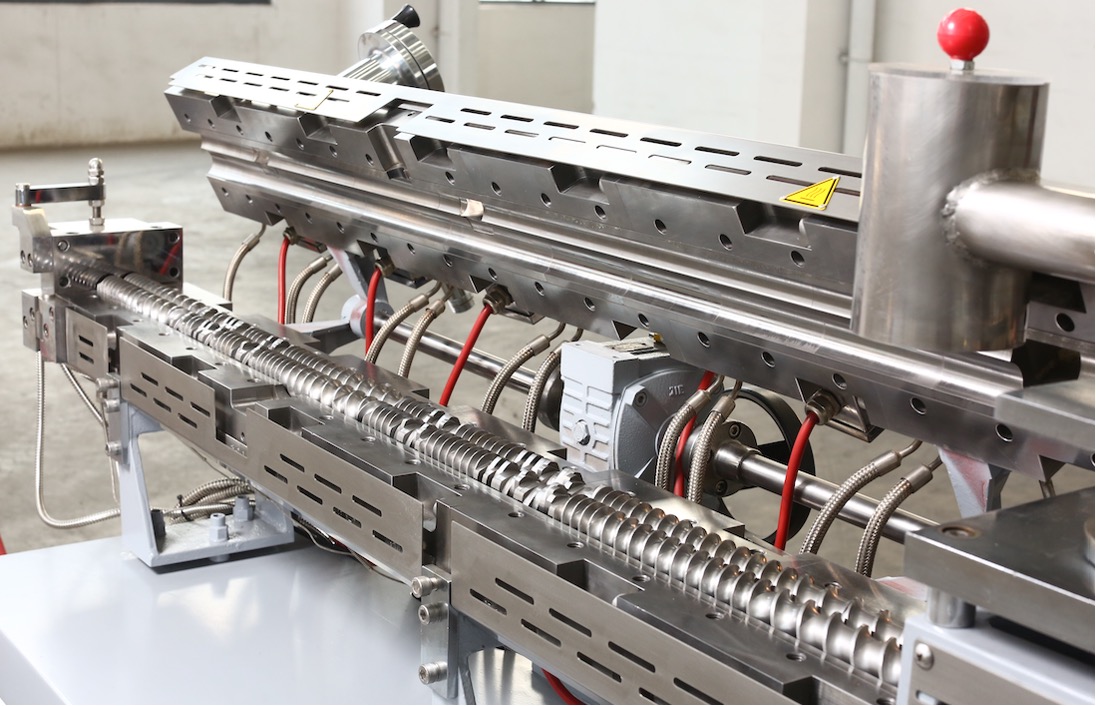

Xinda Twin Screw Extruder Machine: Clamshell Barrel

Jiangsu Xinda Tech Limited is a professional twin screw extruder manufacturer in China. Xinda’s twin screw extruder machine is among the most reliable solutions in the plastic compounding market. They are also highly efficient for modified granulation.

Currently, over 2800 Compounding Lines are running in 65 countries worldwide. We are a compounding system solution supplier of 3M, PolyOne…

Product Quality Index

Energy Generation

| Model | PSHJ-20 | PSHJ-35 | PSHJ-50 | PSHJ-65 | PSHJ-75 | PSHJ-95 | PSHJ-127 | PSHJ-135 |

|---|---|---|---|---|---|---|---|---|

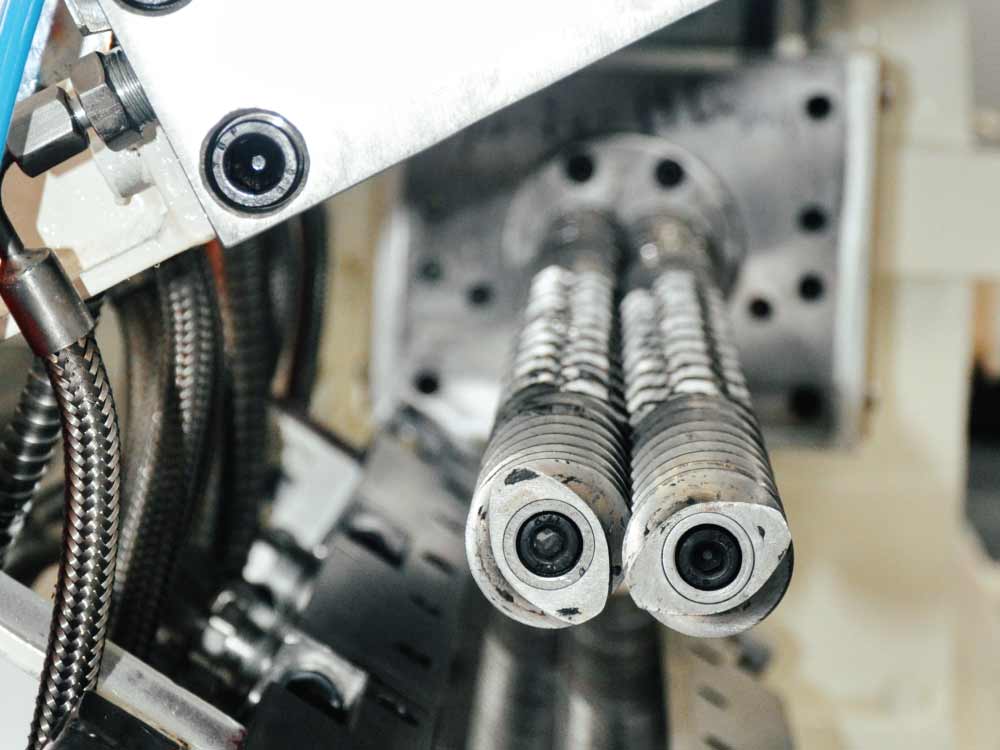

| Twin Screw Diameter:mm |

21.7 | 35.6 | 50.5 | 62.4 | 71 | 92 | 126 | 132 |

| Screw Central Distance:mm |

18 | 30 | 42 | 52 | 60 | 78 | 102 | 110 |

| Twin Screw Length:L/D |

28-52 | 28-52 | 28-52 | 28-52 | 28-52 | 28-52 | 13-18 | 13-18 |

| Main Extruderr Motor Power:kW |

4-5.5 | 18.5-30 | 55-110 | 75-200 | 95-250 | 250-450 | 160-200 | 200-280 |

| Twin Screw Speed Max.:rpm |

600 | 600/800 | 600/800 | 600/800 | 600/800 | 600/800 | 300 | 300 |

| Reference Output kg/hour |

5-10 | 30-120 | 100-300 | 250-450 | 350-700 | 800-2000 | 1000-2000 | 1500-3000 |

Application

We provide our machinery users with consistent high productivity and product quality and the maximum cost effectiveness with XINDA technology. The XINDA co rotating twin screw extruder machine is ideal for precise compounding of polyolefins,engineered plastics and other continuous processes.

Welcome to Xinda

XINDA was founded by Mr. Kong Xiangming in 1988. Since then, Xinda has focused on producing the equipment and supplying the turn-key solution for compounding and extruding industries.

Xinda