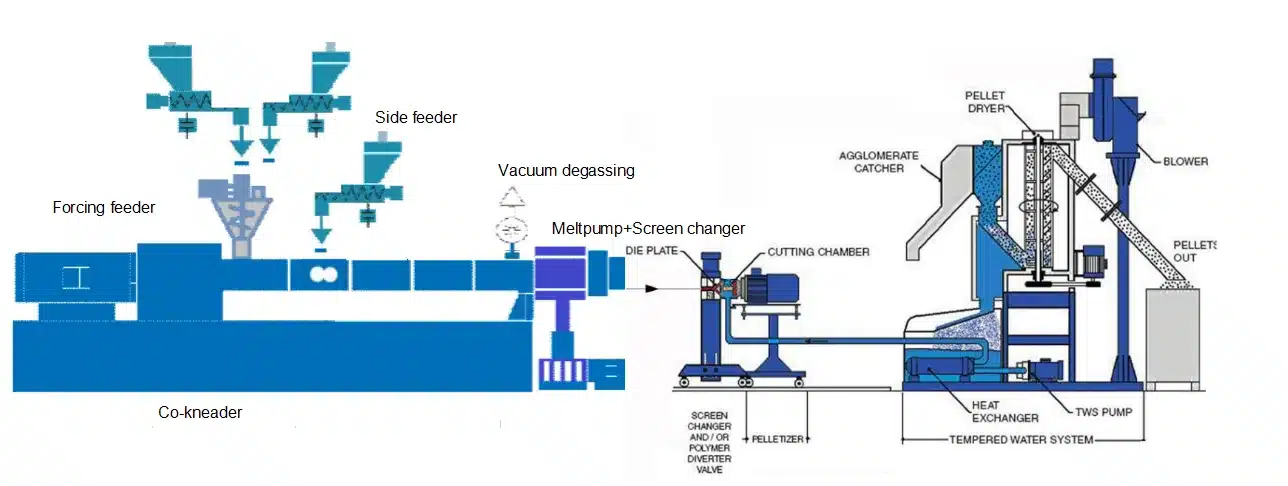

The underwater granulator is dedicated to the production of various polymers and thermoplastics, providing uniform spherical particles for subsequent production, with a yield of up to 12000 kilograms per hour. According to the operation mode, it can be divided into manual type and automatic type. The integrated water treatment system comes with a robust and stable centrifugal dryer, which ensures complete separation of particles from water and full drying of particles, while providing stable flow and temperature process water for the pelletizing process.

Advantages

> Compact and integral design

> Stable and reliable machine performance, low maintenance costs,

> Fully automatic operation, reduced manual intervention.

> Strong operational flexibility, safety, convenience

> Low noise, low energy consumption

> Environmental protection, pollution-free particles.

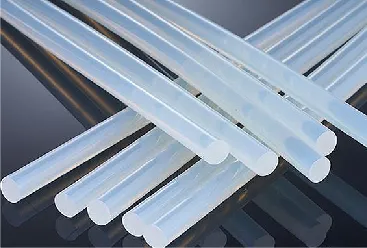

> Excellent quality, rounded shape, smooth surface, and uniform

Details

start up valve

start up valve

The melt reversing valve, also known as the start-up valve, serves as the dividing point between the underwater pelletizing unit and the upstream equipment, connecting or cutting off the pelletizing process and the upstream process. Well-designed and easily operated components can control the melt flow during the production process, providing you with a safe, stable, efficient and economical production process.

die head

die head

The template is one of the core components of the underwater pelletizing unit.According to the characteristics of production and materials, the heating methods for designing templates are usually divided into electric heating and oil heating. According to different production and processing requirements,we tailor a more scientific and reasonable cutting head selection scheme for you.

Water bypass

Early or late entry of water from the underwater granulation process into the cutting chamber can lead to unsuccessful start-up and even direct significant production losses. The bypass pipe can accurately help you control the time when the process water reaches the cutting chamber, thereby maximizing the startup success rate and production efficiency

Spin dryer

Combining different production and processing needs, installing particle dryers beside water tanks or independently around silos is a good choice in actual production. Install a large material separator at the inlet of the dryer to prevent large materials from entering the dryer, thereby extending the service life of the filter screen. Installing a dehumidification fan on the top of the dehydrator can more effectively reduce water content and help with particle drying. With years of dedicated research, XINDA has developed a variety of water treatment systems to meet the production requirements of different materials and processes. The system can provide a water treatment process suitable for any application, including flexible adjustment of cooling and heating of process water, and accurate control of process water temperature. The water system can accurately control the residence time of particles in process water and achieve satisfactory cooling effects.

Gear pump

Gear pump

When the melt pump is used in series with a single screw or twin screw extruder, it can significantly increase the benefits of the entire production line, ensure stable melt pressure and output during production, and provide the required pressure for subsequent pelletizing processes.

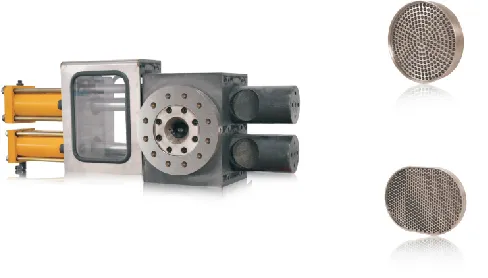

Screen changer

Screen changer

The process of removing impurities from the melt is particularly critical prior to the pelletizing process. Through a screen changer, impurities contained in the melt are filtered and removed, ensuring the purity of the material, thereby stabilizing production.

Spare Parts

connector

connector

knife screw shaft

knife insert

cutterholder

cutterholder

cutter

knife insert

cutterholder

cutterholder

cutter

knife insert

Choose the model

The underwater granulator is the most core device in the underwater granulation process, with a staThe underwater granulator is the most core device in the underwater granulation process, with a stable and gentle feed method to ensure that particles of uniform size and rounded appearance are cut. According to customer requirements, manual and automatic feed modes can be selected.ble and gentle feed method to ensure that particles of uniform size and rounded appearance are cut. According to customer requirements, manual and automatic feed modes can be selected.

| Output | 5-120 kg/h |

120-600 kg/h |

600-1000 kg/h |

1500-2000 kg/h |

2000-3000 kg/h |

3000-5000 kg/h |

More than 5000 kg/h |

|---|---|---|---|---|---|---|---|

| Model | UWP-60 | UWP-95 | UWP-120 | UWP-200 | UWP-300 | UWP-500 | UWP-XL |

Application

Elastomers (TPU,TPE)

Hot Melt Adhesive

Biodegradable Materials

eps

Color Masterbatchs

Engineering Plastics