Application: PC/PS conductive material

Nation: Singapore

Equipment: 3-flight Co-kneader SJW-100

2007: the customer knew Xinda’s co-kneader through some friends in the industry, and started to ask for information about Xinda’s co-kneader. That customer has a German W&P twin screw extruder, but each formula must be repeated twice to achieve the dispersion effect. Subsequently, the customer expressed raw materials to Xinda and tested them on the Xinda test equipment. For the first test, our Co-kneader achieved its dispersion effect the first time; One month later, the second test was carried out with a new screw geometry for better performance. The quality of the finished product was found to exceed the expected effect after the film-blowing test. Finally, he ordered a SJW-100 co-kneader compounding line, including loss-in-weight feeders.

2015: the customer was quite satisfied with the equipment quality and service of Xinda, and then purchased a new SJW-100 PS/PC Conductive Masterbatch Making Machine. So that their equipment could be upgraded from the original one-machine multi-purpose to a single-machine single formula. It also reduced the equipment cleaning and screw combination replacement work during formula replacement, and the production efficiency was improved as well.

2020: they are planning to purchase another set of equipment to meet the increased market demand. We are still negotiating the configuration.

Customer’s Feedback and Review

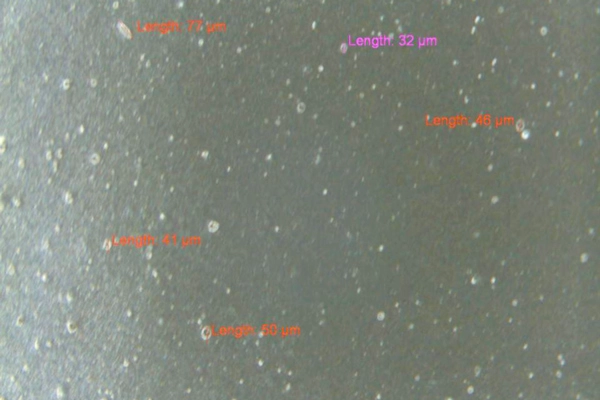

1. XINDA’s employees are very dedicated. Every employee of XINDA we meet is very enthusiastic and helpful. Due to conditions constraints during the test, carbon black has turned every field staff into a black person, and only after washing three times can they be restored to their original state. Such a test lasts 3 days. Very satisfied with the dispersion and temperature control of the reciprocating machine. It’s much better than the dispersion effect of a twin-screw one. The existing German twin screw extruder has been abandoned.

2. The quality of Xinda equipment is the same as that of German equipment. The equipment operating at full load for more than 10 years, it has never been overhauled, and the current status of the equipment is still very good.

3, The service of Xinda is excellent. The after-sales staff will answer all questions and give prompt reply. Spare parts are provided quickly, sometimes spot goods are shipped before receiving money, mutual trust between the two sides is high.

4, Xinda is a reliable partner. The managers, salesmen, technologists and after-sales personnel who started to contact in 2007 have remained unchanged for more than 10 years. Now we are not only partners, but also good friends.