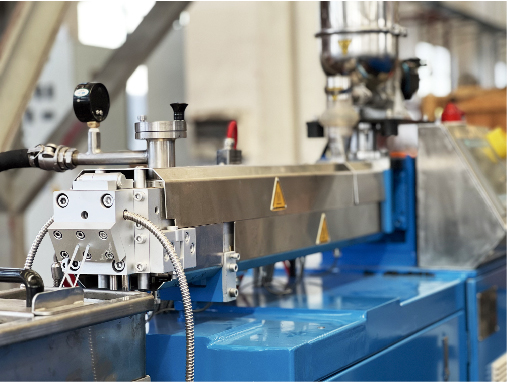

As the main equipment of compounding production, the extruder bears the brunt of its operation difficulty and danger. Today, we will sort out the little common sense you need to keep in mind during the operation and debugging of the extruder and start small to protect safe and efficient production.

Tip 1

Before starting the extruder, check whether there is any foreign matter in the barrel, up and down the hopper and inside, check whether the fastening bolts of each part are loose, whether the safety cover is firm, whether the position of each button switch is correct, and then lubricate each part. Add enough lubricating oil and do a good job of cleaning and sanitation of the equipment.

Tip 2

Before starting the machine, check whether the temperature control is sensitive, whether the instrument is out of order, and whether the cooling water circuit is smooth. Usually, methods such as thermometers and cooling water are used for detection.

Tip 3

Heat the screw, barrel and die head of the extruder according to the extruder operating procedures. After the temperature rises to the set temperature, it must be kept warm for about 10 minutes before starting the machine, so that the temperature of each part of the machine tends to be stable.

Tip 4

Notify staff around the device when you are ready to drive. Before starting the machine, be sure to tighten the connecting screws and bolts of each part of the die while it is still hot. Before the material is extruded, the operator must not stand in front of the die to prevent the bolt or screw from breaking and causing injury.

Tip 5

Start the motor for driving the screw rotation at low speed, and check whether the pointer of the working ammeter of the main motor swings normally.

Tip 6

The test run of the screw should not exceed 30 minutes. After everything is normal, connect the die head and the pelletizing equipment, install the connecting bolts for the die head, and apply a layer of molybdenum disulfide or silicone oil before use to facilitate disassembly.

Tip 7

In the initial stage of feeding production, the screw should use the lowest working speed, and the feeding should be less and uniform. Check whether the pointer of the working ammeter of the motor used to drive the screw rotation changes at any time.

Tip 8

After the extruder is put into normal production, the operator should always check the temperature change of the bearing part. When checking the temperature of the motor and each bearing part, gently touch the inspection part with the back of your finger. Do not touch any rotating parts with your hands during the operation of the equipment.

Tip 9

When dismantling and installing the screw and mold, do not directly hit the parts with a heavy hammer, if necessary, pad hardwood and then tap to disassemble or install.

Tip 10

When cleaning the residual material on the screw, barrel and mold, it must be cleaned with bamboo or copper knives, brushes, or professional water washing and air washing equipment to avoid scraping residual materials with steel knives or continuous use of fire. BBQ parts. Or use special screw cleaning material for cleaning without disassembly.

Attachment: 9 kinds of raw materials when the operation matters when downtime

| PS,SAN | Because the thermal stability of hard glue is good, it will not decompose even if it is heated for a long time at a certain temperature, so it is only necessary to turn off the heat before shutting down. |

|---|---|

| ABS | The thermal stability of this compound is also good, and there is no need to push out and clean the remaining compound in the barrel during shutdown. |

| PC | Due to the temporary suspension of production (such as the night shift does not start), it is necessary to keep the barrel at 160 ° C to avoid the rubber material being damp. If the material needs to be changed, it is necessary to use PE to clean the barrel, and take out the screw from the hot barrel. Use a copper wire brush cleaning screw |

| PVC | This is a heat-sensitive rubber compound. Before stopping, first turn off the electric heating, and then push out the PVC until the temperature of the barrel drops to 150°C, and then use another rubber compound with better thermal stability to push out all the rubber material in the barrel. |

| PMMA | Although the rubber compound is easily thermally decomposed at high temperature, the thermal stability is still good at normal temperature, so it is only necessary to turn off the electric heating when the machine is shut down. |

| PA | The thermal stability of the rubber compound is still good. There is no need to clean the barrel or push the material clean when the machine is shut down, but the electric heating must be turned off immediately, otherwise the rubber compound will be easily damaged after 15 minutes. |

| POM | Because it is heat sensitive, when the machine is shut down, the pressure should be zeroed ten minutes before the electric heater is turned off, and then continuous injection, push out the rubber material in the barrel, and then use PE to clean the machine. |

Tip 11

When dealing with the failure of the extruder, the extruder is not allowed to run. When the extruder screw is rotated and the mold is adjusted, the operator is not allowed to face the mouth of the extrusion barrel to prevent accidents.

Tip 12

When the extruder is in production, the operator is not allowed to leave the post. If it is necessary to leave, the extruder should be stopped.

Tip 13

Disassemble the screw after parking, and apply a layer of anti-rust oil after cleaning the residual material. If it is not used temporarily, it should be wrapped and hung vertically in a dry and ventilated place.

Tip 14

For extruders and accessories that have been shut down for a long time, they should be coated with anti-rust oil and sealed to prevent foreign objects from entering.

Disclaimer: (part of) the data, charts or other content in this article are from the Internet or other publicly published materials, and are only for readers’ reference, communication, and learning, and do not involve any commercial behavior or purpose. The copyright belongs to the original author and source. If the copyright owner believes that this article is suspected of infringement or other problems, please contact us and deal with it in a timely manner.