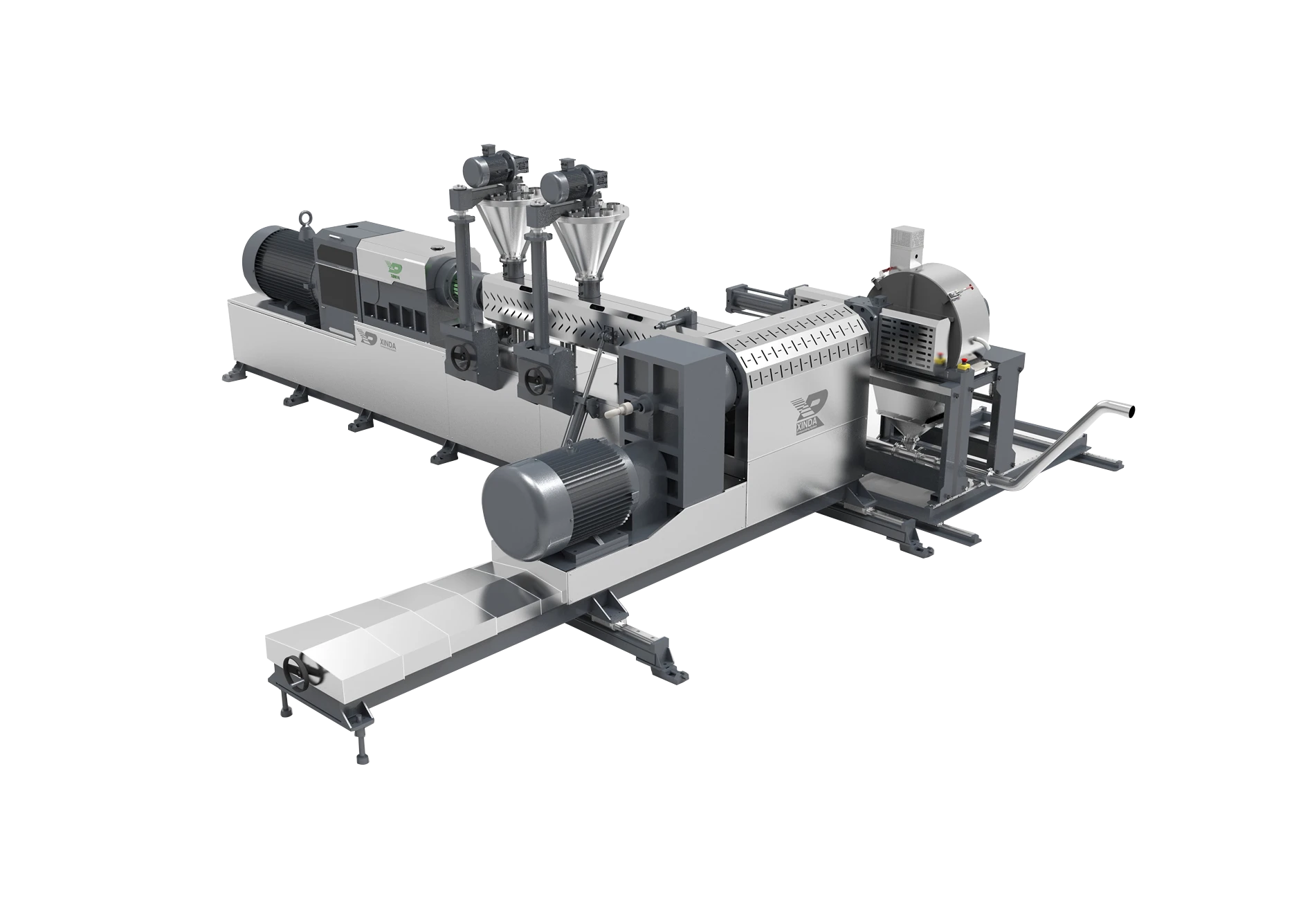

With the rapid growth of the polymer materials industry, the development and use of reciprocating kneading and extruding systems have become more appealing. The performance of single-screw and twin-screw extruders often can’t meet the needs for blending, filling, reinforcement, and toughening. Using co kneader to produce high-tech, high-value-added products is becoming a trend.

To give polymers certain traits or specific performance during polymer processing, it’s often necessary to blend different polymers or mix them with additives and pigments. The co-kneader provides uniform shearing, high dispersion, high filling, and melt stretching. It combines the advantages of single and twin-screw extruders with a unique working principle and comprehensive thread combination components. This makes it more versatile. One machine can handle mixing, kneading, plasticizing, dispersing, shearing, stretching, degassing, and granulation. This results in a larger melt interface area than typical shear flow.

I. The structure is different from single- and twin-screw extruders

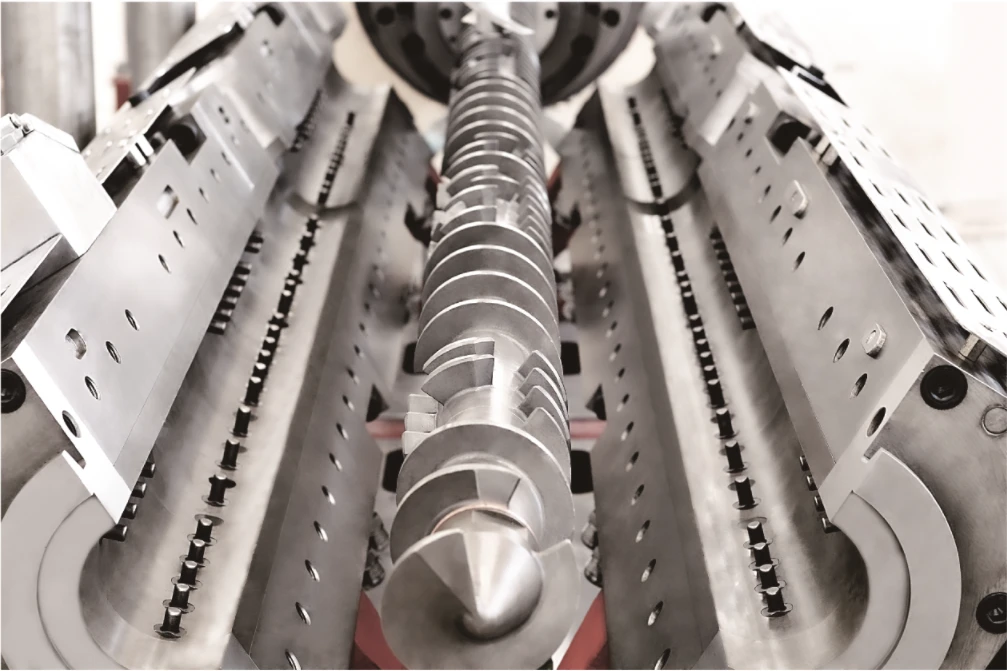

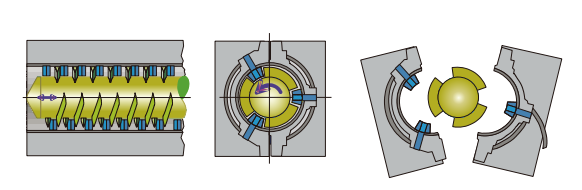

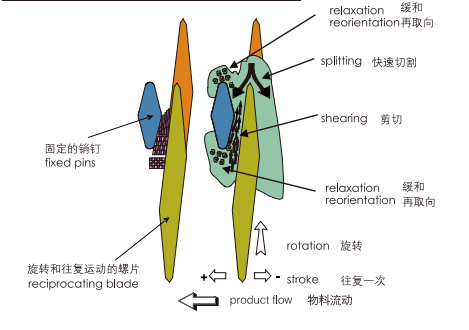

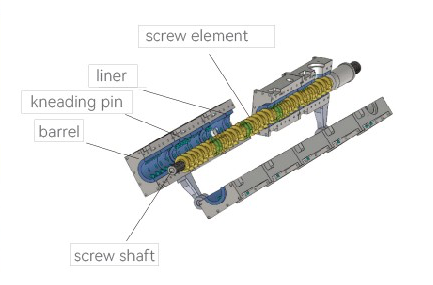

The co-kneader features a unique screw design on the core shaft, divided into three parts per pitch, known as the mixing screw block. Correspondingly, there are three rows of mixing pins on the barrel’s inner sleeve. The screw performs radial rotation and axial reciprocating motion, moving axially with each rotation. This special motion, along with the mixing screw block and pins, ensures the material is sheared and transported back and forth between the pins and the trapezoidal mixing block. The countercurrent motion adds useful axial mixing to the radial mixing. The melt is continuously cut, turned, kneaded, and stretched, interrupting simple lamellar shear mixing.

II. Can prevent material from degradation

Simultaneous radial and axial mixing enhances the mixing effect, ensuring optimal dispersion and distribution, and resulting in a short homogenization time. The interaction between the mixing pin and screw block also improves the barrel’s self-cleaning ability. By appropriately combining screw blocks, stable working pressure is maintained, preventing uncontrollable pressure and temperature fluctuations and avoiding material degradation in the barrel.

III. Screw torque deformation is small

Since the kneading element’s thread is interrupted, the pressure on the polymer is minimal, preventing significant temperature rise. Single- and twin-screw extruders shear thin-layer polymers under high shear and pressure, causing a large temperature rise in the melt, which affects low-temperature extrusion. In contrast, the co-kneader, with the same diameter, has a smaller aspect ratio and transmits torque over a shorter distance, resulting in less screw torsional deformation.

I. Modular Design and Efficient Mixing Mechanisms

The main machine barrel and screw are assembled like blocks. The barrel is made of multiple groups of open and closed hole cylinders. The clam-shell barrel can be opened quickly for easy cleaning and maintenance. The screw consists of various mixing and conveying screw blocks mounted on a mandrel. The barrel and screw can be flexibly configured to suit different materials and process requirements.

The unique design of the gear box and swing box enables the screw to perform axial reciprocating motion while rotating. Each screw rotation includes one reciprocating motion, with the thread interrupted three times, creating a strong mixing effect. This effect is axial rather than radial and occurs between the thread and the pin. All materials in the screw channel experience uniform shear stress, rather than just a thin layer being sheared.

II. Advanced Feeding and Temperature Control Systems

Accurate measurement and reasonable feeding methods are key to strictly implementing the formula, and the first step to ensuring product quality. Based on material performance and user needs, we offer various feeding methods, such as volume measurement and dynamic weight loss measurement, to meet different product requirements.

The system features a forced feeding screw and side twin-screw feeding to prevent material buildup at the feeding port. This ensures proportional feeding of each component material simultaneously, solving the environmental pollution issues caused by premixed materials.

This machine utilizes a Siemens frequency conversion speed control device known for its excellent performance and reliability. The barrel features electric heating and water cooling (or oil heating and cooling), equipped with a secondary pressure sensor, six sets of RKC intelligent temperature control devices, two-way PID adjustment, and four sets of melt temperature sensors deep inside the barrel. This setup accurately reflects the melt’s temperature in each zone. Additionally, it includes a multi-point temperature inspection instrument for precise temperature control with minimal errors. Advanced mechanical and electrical interlocking devices provide dual overload protection, ensuring equipment and personal safety. The control cabinet includes an analog display board, providing intuitive and clear rotation status for each unit part.

III. Comprehensive Extrusion and Granulation Processes

Advanced Melt Pump System

The melt pump’s role is to pressurize high-temperature polymer melt from the extruder and deliver a stable flow rate to the extrusion die after pressure clearance. Regardless of changes in extruder pressure or flow rate fluctuations, the melt pump consistently supplies material to the die. Its core component is the gear, which squeezes and transports melt between its teeth while closing low-pressure cavities to reduce backflow and lower processing temperature, aiding in establishing higher output pressure. Involute helical gears are used to increase gear meshing overlap, ensuring continuous, smooth material transport, reducing pressure fluctuations, and achieving stable melt conveyance. The helical gear also offers self-cleaning properties to prevent material deposition and decomposition.

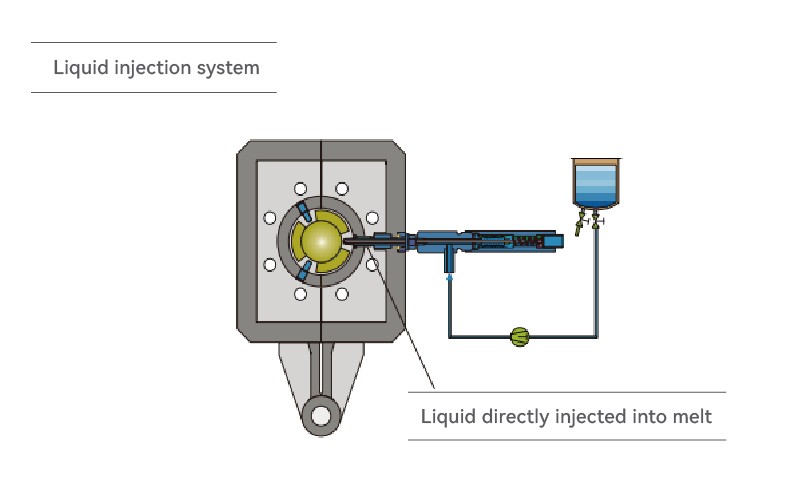

A heating and cooling device regulates the melt pump’s temperature within an optimal range. Heating methods include electric and oil heating. While the co-kneader is not suited for plastic molding, a melt pump is installed post-extruder and connected to the molding die. This process combines mixing and modification with molding, reducing granulation steps and thus cutting costs, shortening production cycles, saving energy, and eliminating the thermal history of secondary processing and plasticization. The melt pump includes pressure sensors for accurate pressure measurement, aiding in process adjustment.

Two-Stage Granulation Unit

The system features a two-stage granulation unit utilizing equidistant and equal-depth single-screw extruders to transport the melt. Its purpose is to complete plasticization and longitudinal mixing and establish stable extrusion pressure. The low speed of operation minimizes shear heat in the material, ensuring optimal temperature control. This setup is particularly beneficial for low-foaming, heat-sensitive products, such as PVC, as it separates the mixing and pressure-building processes into two steps. Once the melt is plasticized, it’s transported to the extrusion die at a constant pressure, temperature, and quantity, preventing degradation of heat-sensitive and shear-sensitive materials. The system delivers high output and stable product quality, with optimized mixing processes unaffected by material manufacturing. Additionally, a vacuum exhaust device is provided during material entry into the screw, offering a larger exhaust area, increased material surface area change, and ample exhaust time for superior exhaust performance compared to single-stage exhaust extruders.

Flexible Cutting Methods

The system offers various cutting methods including drawing water-cooled pelletizing, hot-cut water-cooling, hot-cut air-cooling, etc. These methods can be tailored to different materials and user preferences.

IV. Exhaust and Self-Cleaning Systems

Self-Cleaning Mechanisms

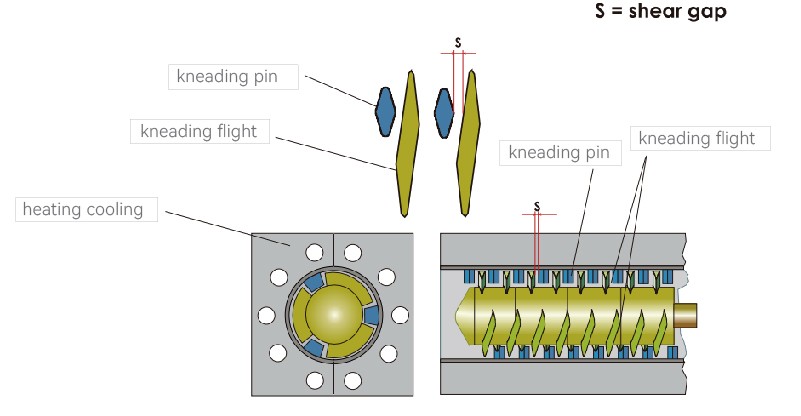

The threaded components are arranged in a building block style on the shaft, allowing flexible combinations for different needs. Three rows of pins are installed on the inner liner, with six types of pins used:

- Solid long pins: Fix the inner liner sleeve and enhance mixing.

- Hollow long pins: Fix, mix, install temperature heads, and inject liquid additives.

- Long flat-head pins: Fix the inner liner.

- Flat-head pins: Block spare holes.

- Solid pins: Aid in mixing.

- Short solid pins: Crush material at the feed port.

As the screw reciprocates, the relative motion of the pins and screw blocks forms an ∞ curve. When the kneading pin passes through the thread gap, axial material exchange occurs. Each screw revolution causes the pin to shear the material, while the screw and barrel are cleaned axially and radially. This ensures thorough mixing, kneading, and self-cleaning in a reciprocating compounding extruder.

The pins act as agitators, redistributing the material. The interrupted threads cause the material to flow back, undergoing shearing, orientation, cutting, folding, and stretching. The melt is both recombined and further divided. In each L/D channel, the melt divides four times. This explains why the reciprocating extruder operates with a short aspect ratio, achieving effective mixing and ensuring no dead ends in the barrel. It has excellent self-cleaning ability, high conveying efficiency, and stable, uniform material residence time.

Exhaust Systems

The main machine barrel features a vacuuming device and a natural exhaust device. The forced feeding hopper and side feeding also have natural exhaust devices. These ensure thorough removal of moisture and various volatile gases generated during processing.

Content source: PTOnline, Xintec Translation

Disclaimer: The data, charts, and content in this article are sourced from the Internet or publicly published materials. They are for reference, communication, and learning only, with no commercial intent. Copyright belongs to the original authors and sources. If any copyright owner believes this article infringes on their rights, please contact us for timely resolution.