How does the gravimetric feeder complete the feeding process?

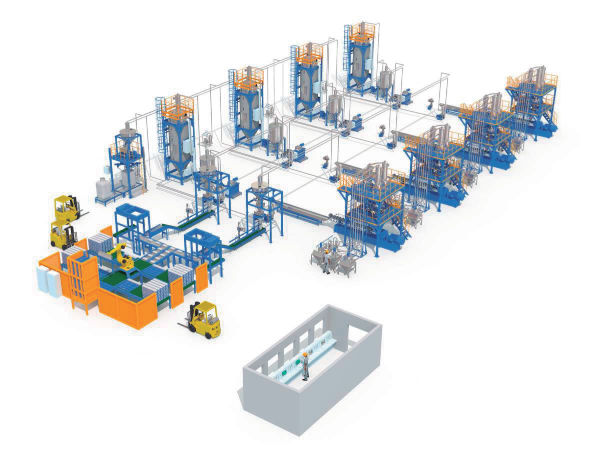

There are many types of gravimetric feeders, including single-screw gravimetric feeders, twin-screw gravimetric feeders, and liquid gravimetric feeders.

The feeding process can be divided into three steps:

When the gravimetric feeder works, the material in its weighing hopper gradually decreases. When the material reaches the set weight, the feeding device automatically starts to replenish it. The gravimetric feeder then works at a fixed speed. When the material reaches the set weight, it stops feeding. The equipment then switches to weightless mode automatically.

The weighing sensor of the gravimetric feeder is linked with the weighing controller. Each collected data item will be transmitted to the controller, and then the controller will perform calculations, and the calculation results will appear on the display screen. Through the data displayed on the display screen of the gravimetric feeder, we can not only view and monitor various data intuitively but also control the working speed of the gravimetric feeder in time process:

During the precise discharging process of gravimetric feeder, the control system will collect data at a high speed, and can calculate the reduced mass within a certain period of time to determine the speed and accuracy of the gravimetric feeder discharging.

What are the requirements of the gravimetric feederfor materials?

Gravimetric feeders require very high measurement accuracy, so their design ensures high precision. The system is sealed to maintain precision and prevent environmental contamination. This equipment is suitable for powdery, granular, and liquid materials. These materials tend to scatter, stick, adsorb, and volatilize easily. Therefore, the process must address these characteristics to meet different requirements.

In addition, for some chemical enterprises with special requirements, the loss-in-weight system also needs to have explosion-proof settings, which can meet the requirements of plant construction and national safety management.

The measurement of the gravimetric feeder is a combination of static measurement and dynamic detection. During use, there will be a series of parameters and time settings. In actual production, when there is a possible out-of-tolerance situation, an alarm function is set in the gravimetric feeder, which can effectively prevent the occurrence of problems.

Disclaimer: This article’s data, charts, and content are sourced from the Internet or publicly published materials. They are for reference, communication, and learning only, with no commercial intent. Copyright belongs to the original authors and sources. If any copyright owner believes this article infringes on their rights, don’t hesitate to get in touch with us for a timely resolution.