High-speed mixing is to put pigments, dispersants, carriers, etc. into a high-speed mixer for high-speed mixing according to the designed formula. It is an extremely important first production link in the production of color masterbatches.

Practical experience has proved that the pre-wetting of the pigment in the high-speed mixing process largely determines the final dispersibility of the color masterbatch product.

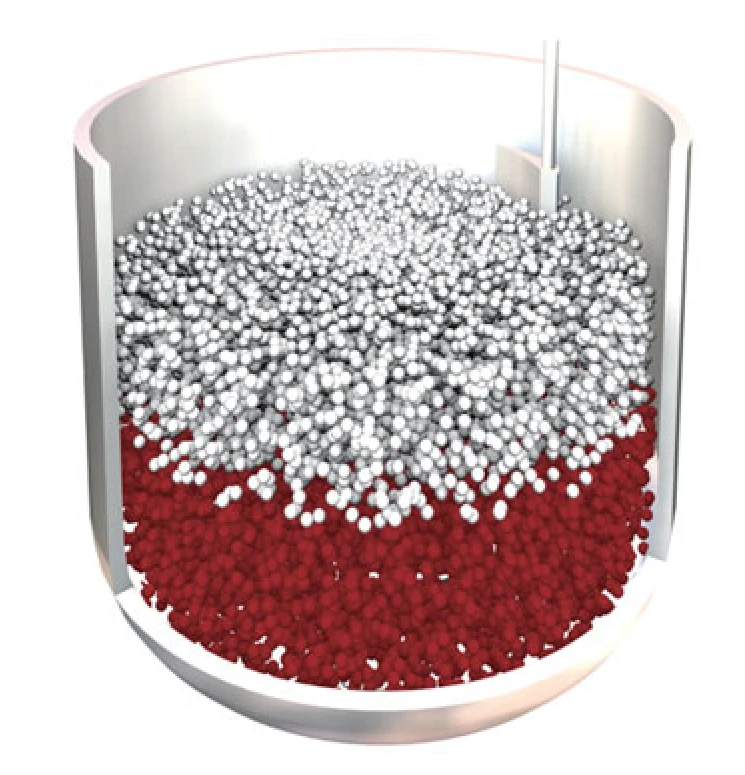

Non-operating

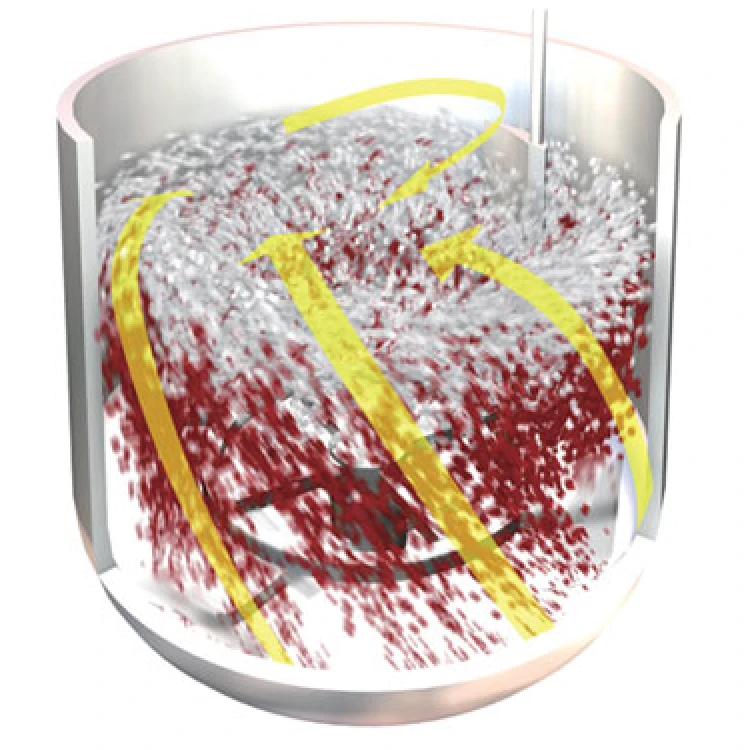

Initial mixing

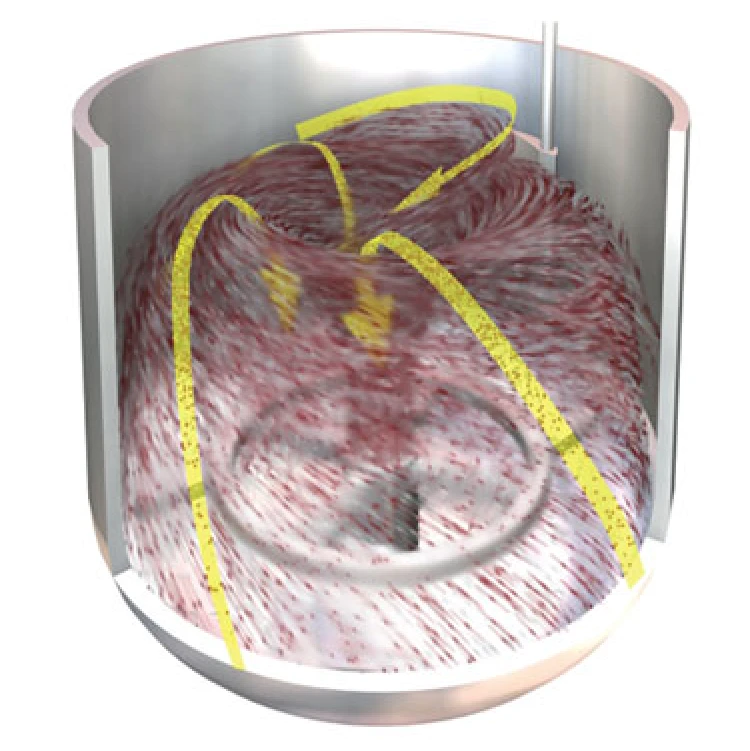

High-speed mixing

I. The quantity and rotation speed of the material carried by the high-mixing process

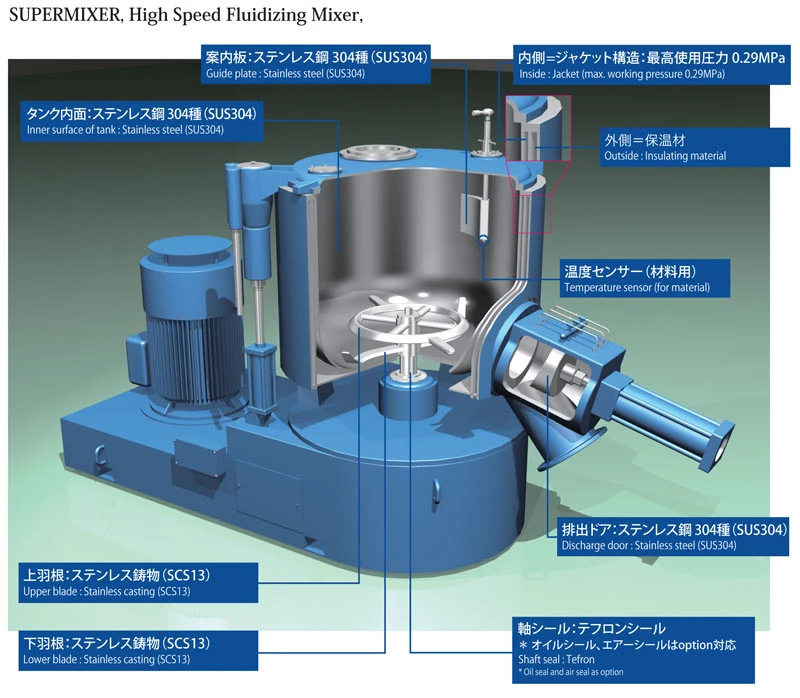

The high-mix loading capacity is related to the bulk volume of high-mix materials. Too much or too little loading will affect the normal operation of high-mixing, and it is difficult to achieve good high-mixing quality. The high-mixing speed is generally divided into two gears: low-speed start-up to reduce power load; high-speed mixing and moistening and discharging, with exceptions for special structures.

II. High mixing process temperature and time

If the high-mixing process does not have a certain temperature, it only plays the role of mixing at room temperature, and the initial wetting of the pigment cannot be achieved, and the key role of the high-mixing process is lost. There are two ways for the heat source of the high-mix process:

(1) To transfer the temperature through the high-mixer barrel oil heating, it is necessary to set the temperature control;

(2) The temperature is transferred through the high-speed stirring and friction of the material, but the first pot of high-mixing takes a long time to accumulate the temperature.

III. The high-mixing process requires careful observation. There are two ways to observe:

(1) A transparent observation port is provided to observe the changing state of the material at any time, but the transparent window is easily contaminated and affects the observation effect;

(2) Indirect judgment through current changes.

Due to inertia, resistance is very large at the beginning of high mixing. The power equipment starts with a high load, causing the current to jump up instantly. After entering normal constant speed operation, the material is loose and moves at a constant speed. The load on the power equipment is very light, and the current decreases accordingly. As the temperature increases, the dispersing wetting agent gradually melts. The adhesion between materials becomes more serious, causing the motor load to increase. The current pointer gradually rises in a wave-like jitter.

IV. High-mixing quality judgment

After high-mixing, if the material remains loose with dry powder flying, it is unqualified and needs reworking. If large lumps form or the material hardens at the bottom, it also needs reworking. Ideally, there should be no dust, and the material should appear granular. Pigments should be wetted and stick to the carrier. The largest particles should enter screw granulation smoothly. Ensure water removal during the high mixing process for quality.

—Photo from KAWATA

V. High-mixing environmental protection requirements

High-mixed material pouring, stirring and discharging will generate certain dust and gas, which is the focus of environmental protection control.

At present, most enterprises install inverted funnel-shaped dust collection equipment above the high-mixing equipment. They suck most of the dust and gas into the pipeline through suction. The gas is then transmitted and filtered for treatment and release. Solid waste is collected and disposed of.

Content source: Plaschain, Xintec Translation

Disclaimer: (Part of) the data, charts, or other content in this article comes from the Internet or other publicly published materials, and is for readers’ reference, communication, and learning only, and does not involve any commercial behavior or purpose. The copyright belongs to the original author and source. If the copyright owner believes that this article is suspected of infringement or other problems, please contact us and deal with it in time.