Application:10KV, 35KV peroxide crosslinked XLPE cable compounds

Nation: China

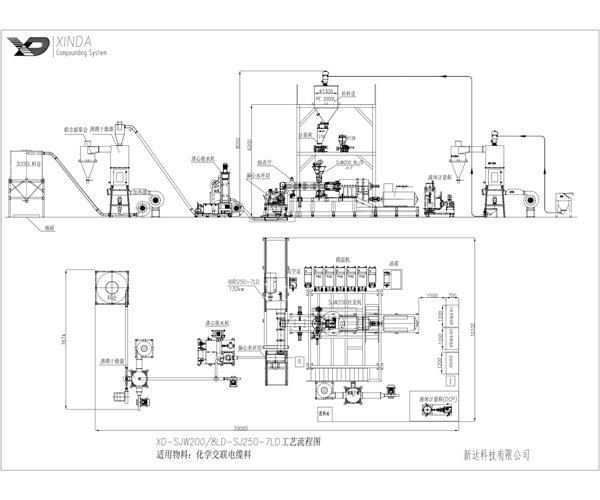

Model: SJW-200 Co-kneader (4 sets)

1.2010-2019: The customer purchased SJW-200 (4 sets) for 10KV, 35KV peroxide XLPE cable compounds machine. They had better performance in compound quality, automatic control, and less powder pollution in their workshops.

2. 2010-2019: Every single line of SJW-200 Co-kneader reached the capacity of 11000MT/Per year.

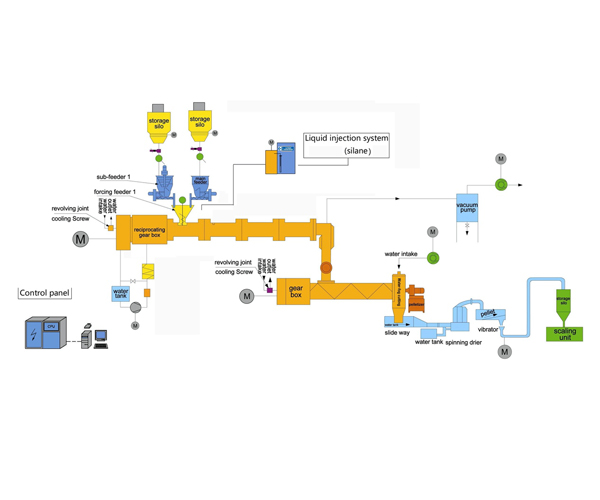

1. Due to the special working principle of co-kneader (low-shearing & high-dispersion), the polymer, additive, and DCP crosslink additives were well mixed and kneaded with more precise temperature control. The final compounds were of high quality due to well dispersion and distribution. The Co-kneader can produce different formulas, including 10 KV, and 35KV XLPE compounds.

2. Each material (PE, additives, DCP) was kept in the silo/Hopper and dosed by a loss-in-weight feeder, which realized the automatic control and a clean workshop.

3. SKW-125 co-kneader is high-capacity and low-energy. Compared with traditional compounding machines, the SKW-125 Co-kneader is 20-30% energy-saving. Each day it can save 6-8 workers (3 shits by 8 hours), and it saves cost by 150-200CNY/MT.

4. The co-kneader can be opened due to the clamshell barrel design, and the discharging extruder screw can be pulled out quickly. It is extremely interesting and attractive for the customers while the formula-shifting and machine maintenance.