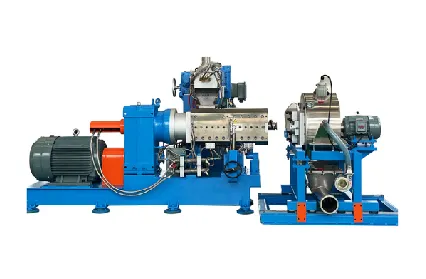

co kneader

Co-kneader(plastic compounding extruder) is one kind of continuous kneader and reciprocating single-screw extruder. Oscilating axial movement combination of discontinuous flights and various pins fixed along the inner wall of barrels guarantee polymers are homogeneously mixing and kneading like making dough. Flexible screw configuration suits for extensive dosing methods.

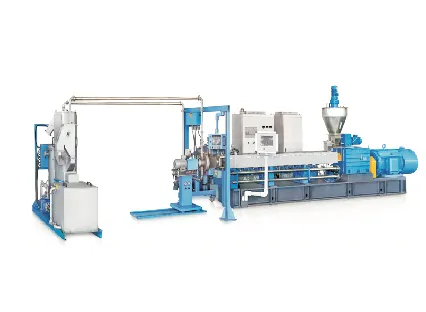

underwater pelletizing system

The underwater granulator is dedicated to the production of various polymers and thermoplastics, providing uniform spherical particles for subsequent production, with a yield of up to 12000 kilograms per hour. According to the operation mode, it can be divided into manual type and automatic type. The integrated water treatment system comes with a robust and stable centrifugal dryer