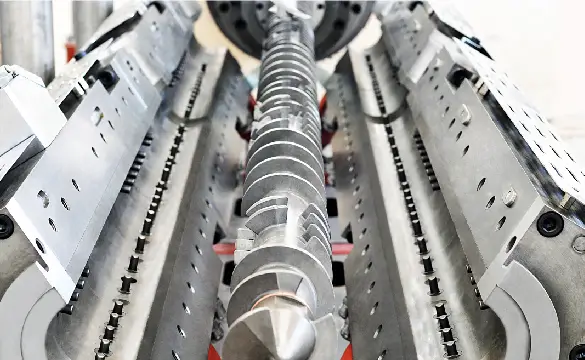

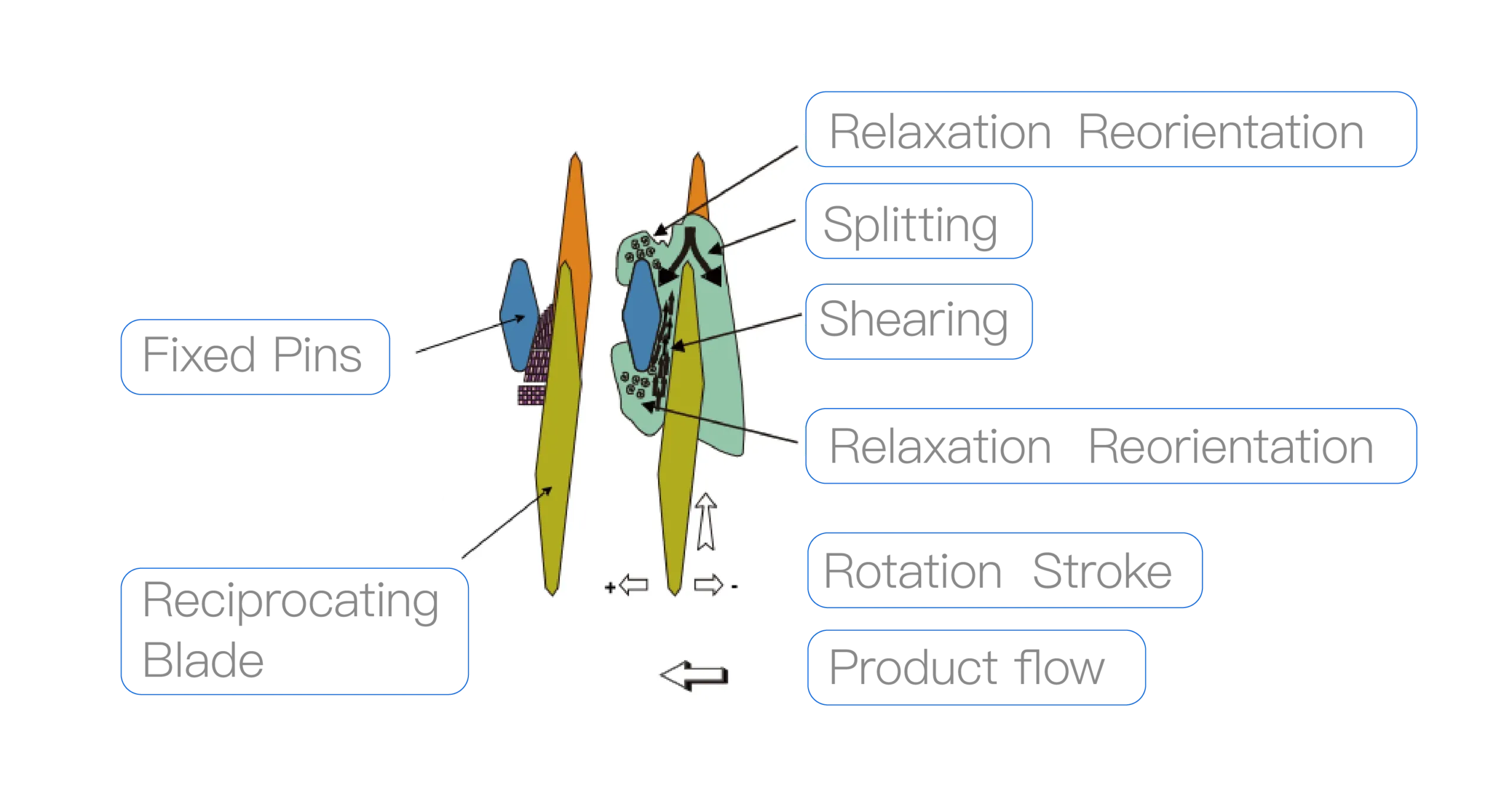

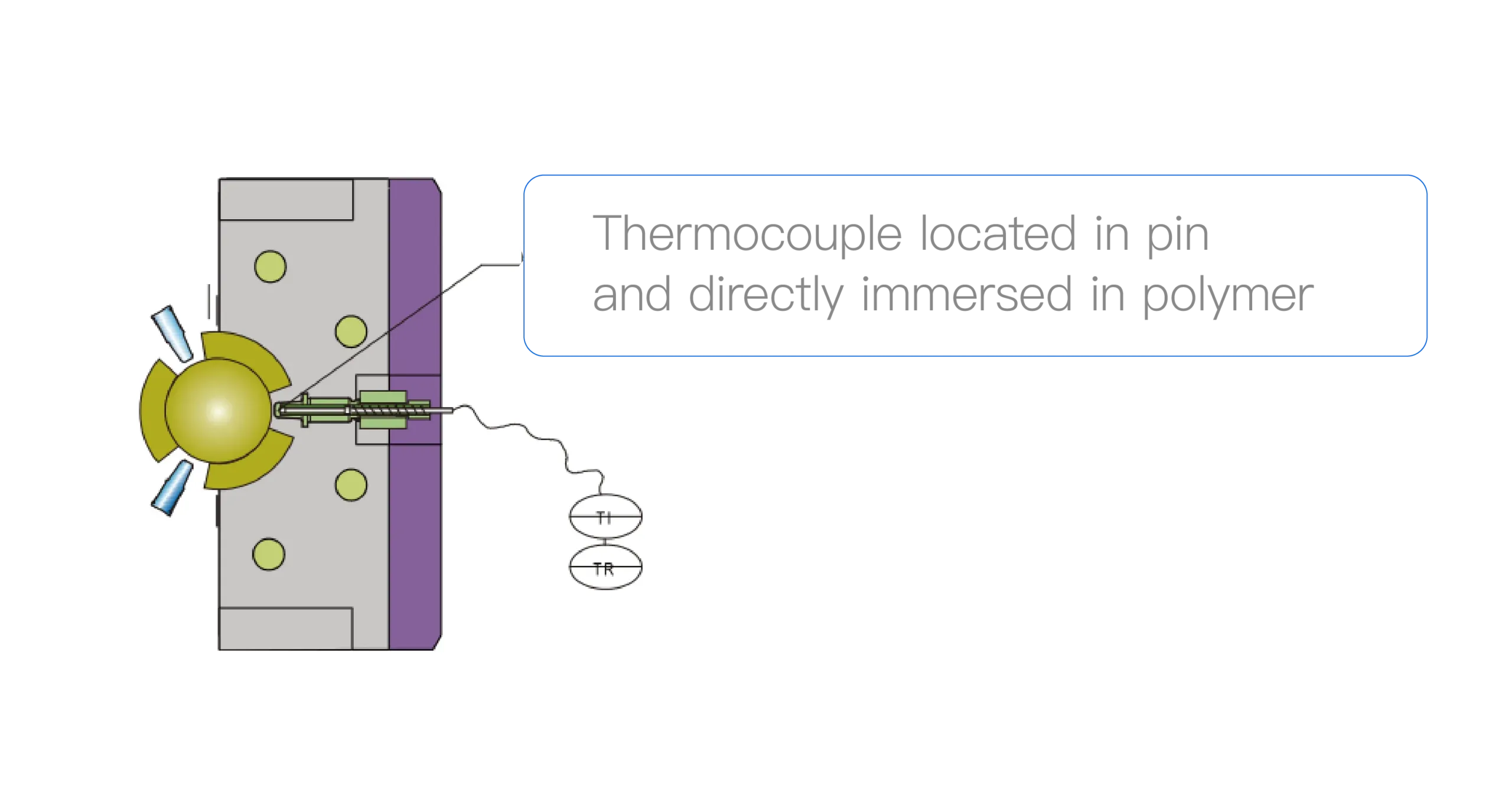

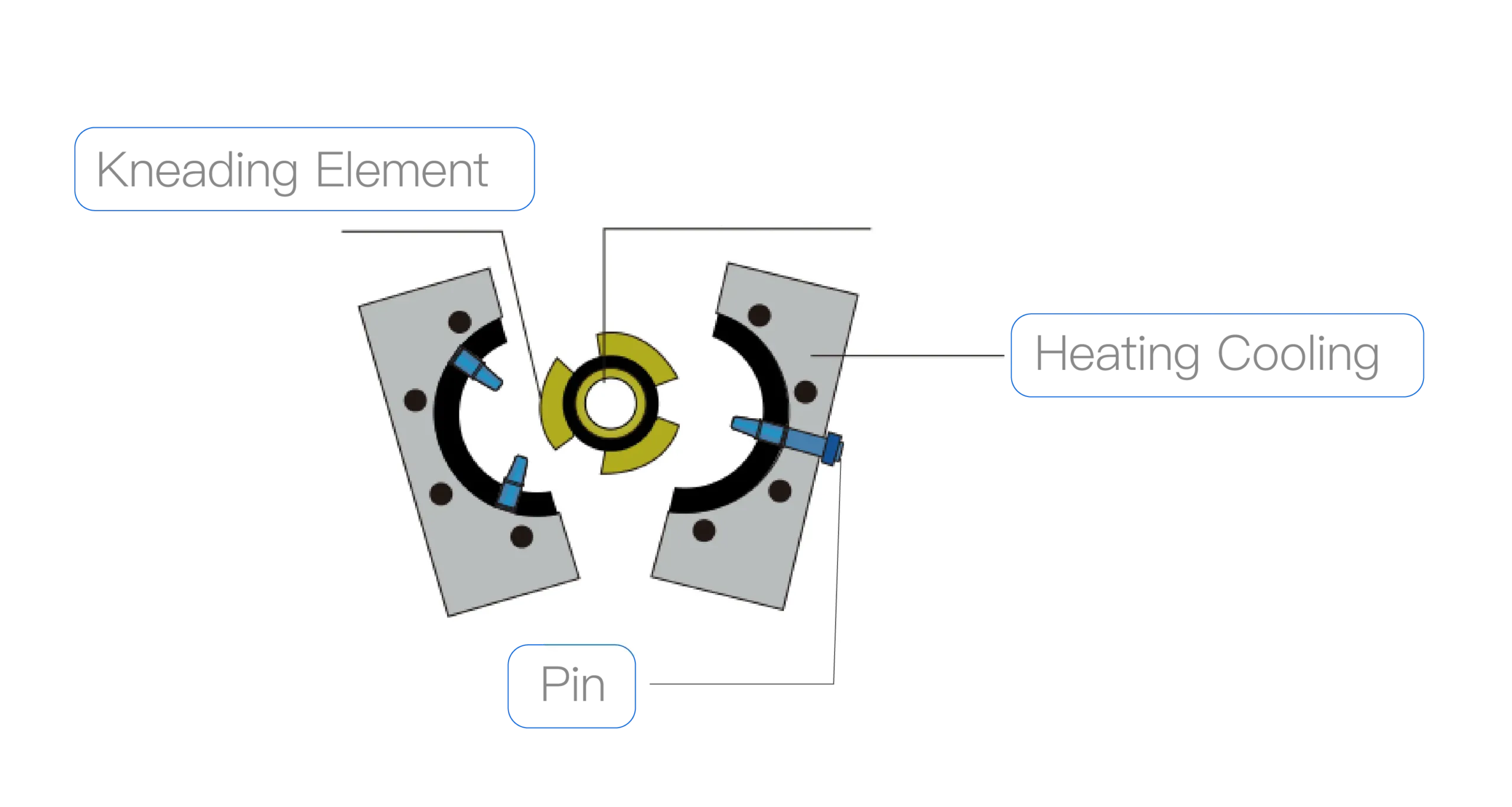

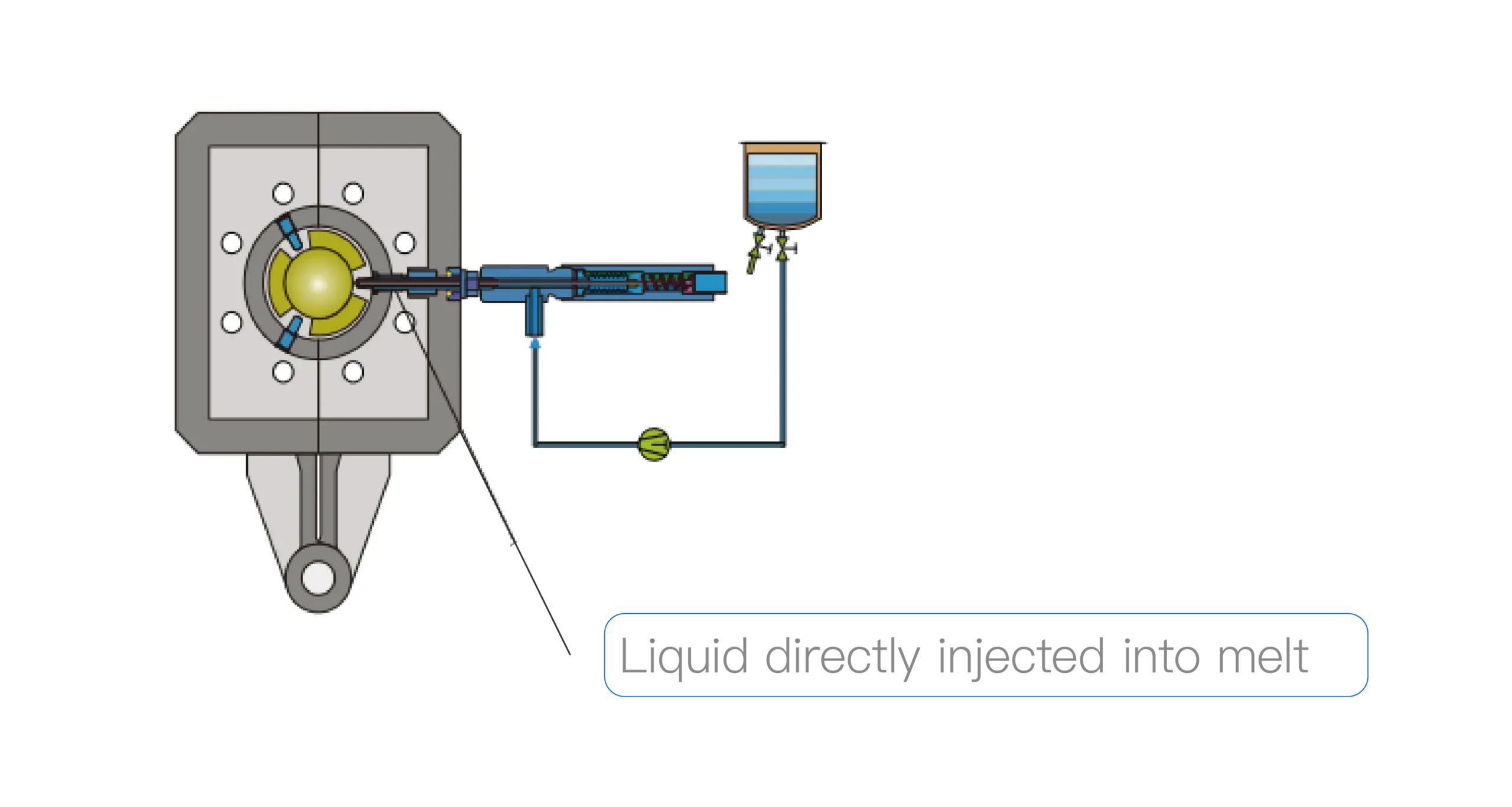

Co-kneader(plastic compounding extruder) is one kind of continuous kneader and reciprocating single-screw extruder. Oscilating axial movement combination of discontinuous flights and various pins fixed along the inner wall of barrels guarantee polymers are homogeneously mixing and kneading like making dough. Flexible screw configuration suits for extensive dosing methods. Fillers or additives (No matter solid or liquid) can be evenly inducted in the melted polymers. Thus the end-pellets can achieve a high quality. Temperature probe immerse into the melts grantees precise temperature control. Welcome to XInda to test our plastic compounding extruder.

Advantages

01

Mild Shear

Ensure the perfect dispersive and distrubutive result

02

Precis Temperature Control

Get the inside temperature of the melt

03

Openable Barrel

Easy for maintenance and cleaning of the barrel

04

Effective Injection

Silane liquid can be injected deep inside the melt

Applications

Three Flights Plastic Co Kneader SJW (C) Series

| Model | SJW-45(M) | SJW-70(M) | SJW-100(M) | SJW-140(M) | SJW-200 |

|---|---|---|---|---|---|

| Screw Diameter(MM) | 45 | 70 | 100 | 140 | 200 |

| L/D | 15-25 | 15-25 | 15-25 | 15-25 | 20-25 |

| Main Motor Power(KW) | 15-30 | 55-75 | 90-132 | 160-220 | 250-280 |

| Max.Screw Speed(RPM) | 500 | 500 | 500 | 500 | 500 |

| Reference Output: KG/HOUR | 10-50 | 100-200 | 150-300 | 600-1000 | 1000-2000 |

Four Flights Plastic Co Kneader SKW & WKS Series

| Model | SKW-105 | SKW-125 | SKW-140 | WKS-120 |

|---|---|---|---|---|

| Screw Dia.(MM) | 105 | 125 | 140 | 120 |

| L/D | 15-22 | 15-22 | 15-22 | 9-15 |

| Main Motor Power(KW) | 200-280 | 350-450 | 550-650 | 250-280 |

| Max.Screw Speed(RPM) | 500/600 | 500/600 | 500/600 | 500/600 |

| Second-stage Screw dia.(MM) | 180 | 220 | 280 | 220 |

| Second-stage L/D | 7 | 7 | 7 | 7-8 |

| Second-stage Power(KW) | 75 | 110 | 132 | 90-132 |

| Reference Output:kg/h | 500-800 | 800-1500 | 1600-2000 | 1800-2500 |